How to maintain the pressure of fermenter

As we know, when wort or beer is fermenting, the fermentable liquid will release amount of carbon oxide.

In the case of conical fermenters like the picture beneath,

How should we control the pressure change in the fermenter?

1. Most of breweries that I ever visited prefer to beer ferment in the atmospheric pressure condition.

The brewer just keep the carbon oxide blow off port open is OK. As carbon oxide molecule is heavier than other air molecule and amount of carbon oxide will run off from blow off port.

Because the flies and bacteria hate carbon oxide, normally the fermentable liquid is very safety. But if the work has a bit of misoperation or improper operation, there is a certain microbiological contamination probability.

2. After some thoughts, we got another method that can keep beer ferment under atmospheric pressure and avoid microbiological contamination.

Connect a soft tube to carbon oxide blow off port, and put the other end of the tube into alcohol liquid.

Please check the picture as below.

This is very saving money, right?

3.Roughly three years ago, our factory adopted electro connecting pressure gauge and electromagnetic relief valve to approach the automatic control of pressure in the fermentation tank. That’s a awesome idea.

Because of some shortcoming, this is not our standard configuration for fermenter.

If you are interested, please send me an email. I believe we can talk more about the device.

If you are interested, please send me an email. I believe we can talk more about the device.

4.With the development of brewery equipment technique, more and more brewers found the pros that beer was fermenting under pressure.

Some theoretical advantages

– The ability to ferment beer at warmer temps without increasing off flavors.

– Overall reduction in yeast ester and fusel production.

– Less vigorous fermentation with reduced krausen, meaning less headspace is necessary.

– Due to the closed fermentation, aroma compounds remain in the beer and aren’t blown off.

– CO2 generated from fermentation can be used to naturally carbonate the finished beer.

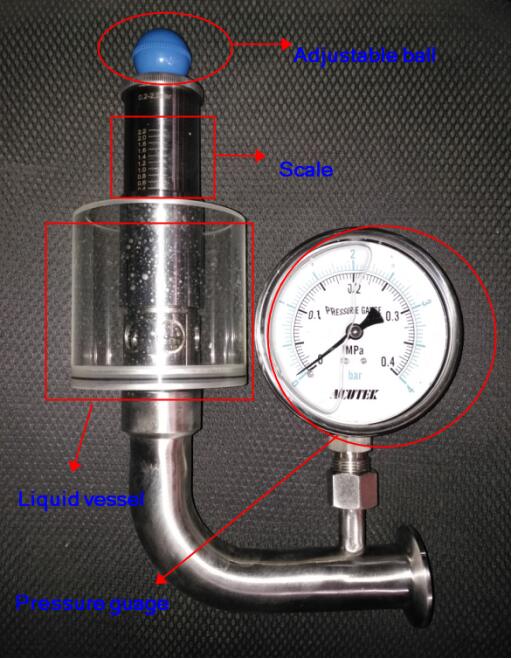

Here I would like to introduce a very handy and safety device to all.

Its name is mechanical bunging valve, that can regulate pressure from 2 psi to 32 psi.

We need to turn the adjustable to set up the pressure you want. The pressure in the picture is 0.4 bar(6 psi) now.

And take some 75% alcohol water or other food grade sterilant into the liquid vessel.

When beer is fast fermenting, we can check the pressure through the pressure gage.

Because of this device, we are not worried about the power cut or other emergencies to lead to abnormal pressure.

Edited by Damon

Get A Quote