What’s heat exchanger

A piece of brewery equipment designed to quickly lower the temperature of wort. Heat exchangers in breweries are often referred to as “plate heat exchangers” because they are made up of corrugated① plates with multiple channels for liquid to flow through. A hot liquid flows along one side of the plate and cold liquid flows along the other side. A heat exchange takes place across the plates.

The type of heat exchanger

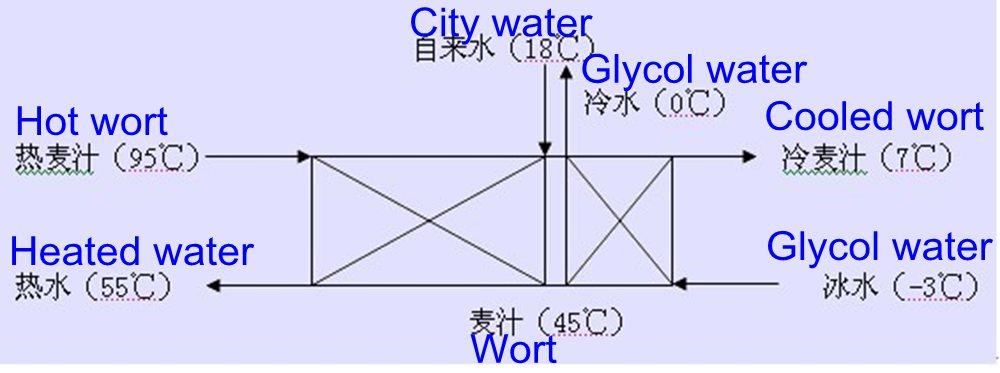

1.Two stage heat exchanger

Normally the Coolants② of first stage is city, second stage is the glycol water.

2.Single stage heat exchanger

Normally the coolant is only cold water. So a cold water tank is necessary.

Advantage of using the cold water for single stage heat exchanging:

1.Energy saving: After heat exchanging, the cold water is heated to perhaps 80°C and is returned to a hot water tank, ready to be used in the next brew or elsewhere in the brewery.

Easier operation: If without the cold liquor tank which means the wort is cooled by the glycol water at the second stage and the glycol will flow back to the GWT, then there will be higher risk on warming the fermentation tank- The wort will warm the glycol to relatively high temperature such as 5℃, so the returned warm gycol water will go to warm the fermenters once it is pumped into the jacket. So to avoid that, a careful monitoring③ from the brewer is required. But this can be totally avoided via choosing a single stage heat exchanger and not using glycol water to cool wort .

2.More sanitary: If there is unknown broken inside the heat exchanger, the cold water will not pollute the wort as the glycol, but just dilute④ the wort.

Important points of heat exchanger:

First stage: City water of around 20℃ can cool the wort from 98℃to 45~50℃.

Second stage: the glycol water of around -3 ℃ can cool the wort to fermentation temperature like 7-20℃. The glycol water becomes about 0℃ to return glycol water tank.

1)Temperature

hot wort at approximately 95°C is run through a heat exchanger, where it is cooled by cold water or a refrigerant coming along the reverse side of the plate in the opposite direction. The wort becomes cool (e.g., to 12°C) and ready for fermentation, and the cold water is heated to perhaps 80°C and is returned to a hot water tank, ready to be used in the next brew or elsewhere in the brewery.

2)Time and efficiency

On average, heat exchangers will be sized so that the entire contents of the kettle can be cooled to fermentation temperature in 45 min or less. A heat exchanger is very energy efficient because the heat originally used to bring wort to the boil is partially reused to heat cold water coming into the brewery.

3)Other Applications

Using refrigerants such as glycol, plate heat exchangers can also be used to cool beer to low temperatures after fermentation, say from 12°C to –1°C, for cold maturation. Heat exchangers may be used in many aspects of the brewing process to heat and cool beer and to heat or cool liquids such as water.

cooled water is passed through the coolant side of the heat exchanger while beer is pumped through the other side allowing for a "chilling" of the beer with extreme efficiency; especially given that there are so many plates to transfer cooling within this design.

4)Working Pressure

The plate heat exchanger with resistance at about 0.25-0.35Mpa,so the wort and coolant need to be pressed inside with pump.

5)Frame

The frame of the heat exchanger must be carbon steel. We all know the hardness of carbon steel is much better than stainless steel. All of the inside plates are pressed together with the backplate, so the backplate is easily out of shape under the huge pressure if it is without enough hardness. Then there will be gap between the inside plates or between the inside plate and backplate. The result is serious, it may pollute your whole batch of beer.

Advantage of heat exchange

1.Easy to Remove and Clean

You simply remove the tie bolts and slide back the movable frame.

The plate pack can then be inspected, pressure cleaned, or removed for refurbishment① if necessary.

2.Expandable

A significant benefit of the plate heat exchanger is that it is expandable, allowing an increase in heat transfer capability. As your heat transfer requirements change, you can simply add plates instead of buying an entire new frame unit, saving time and money.

3.High Efficiency

The pressed plate patterns② and narrow gaps allow for very high turbulence at relatively low fluid velocity. Combined with counter③ directional flow results in very high heat transfer coefficients.

4.Compact Size

The high efficiency requires less heat transfer area resulting in a much smaller heat exchanger than he identical④ effectiveness of other heat exchanger types. Typically a plate heat exchanger requires 20-40% less space than required by a shell & tube heat exchanger.

5.Avoid cross contamination⑤

Each medium is individually gasketed⑥ and as the space between the gaskets is vented to the atmosphere, cross contamination of fluids is eliminated.

6.Less Fouling⑦

Very high turbulence is achieved as a result of the pattern of the plates, the many contact points, and the narrow gap between the plates. This combined with the smooth plate surface reduces fouling considerably compared to other types of heat exchangers.

Edited by Damon from Tiantai Brewery Equipment

Email:[email protected]

WhatsApp: +86 18888339489

.jpg)

Get A Quote