| Function: Store Beer |

| Capacity: DIN 20L |

| Size(Diameter*height): Φ363*307mm |

| Material: SUS 304 2B |

| Top Ring: 1.5mm |

| Body: 1.5mm |

| Bottom Ring:1.5mm |

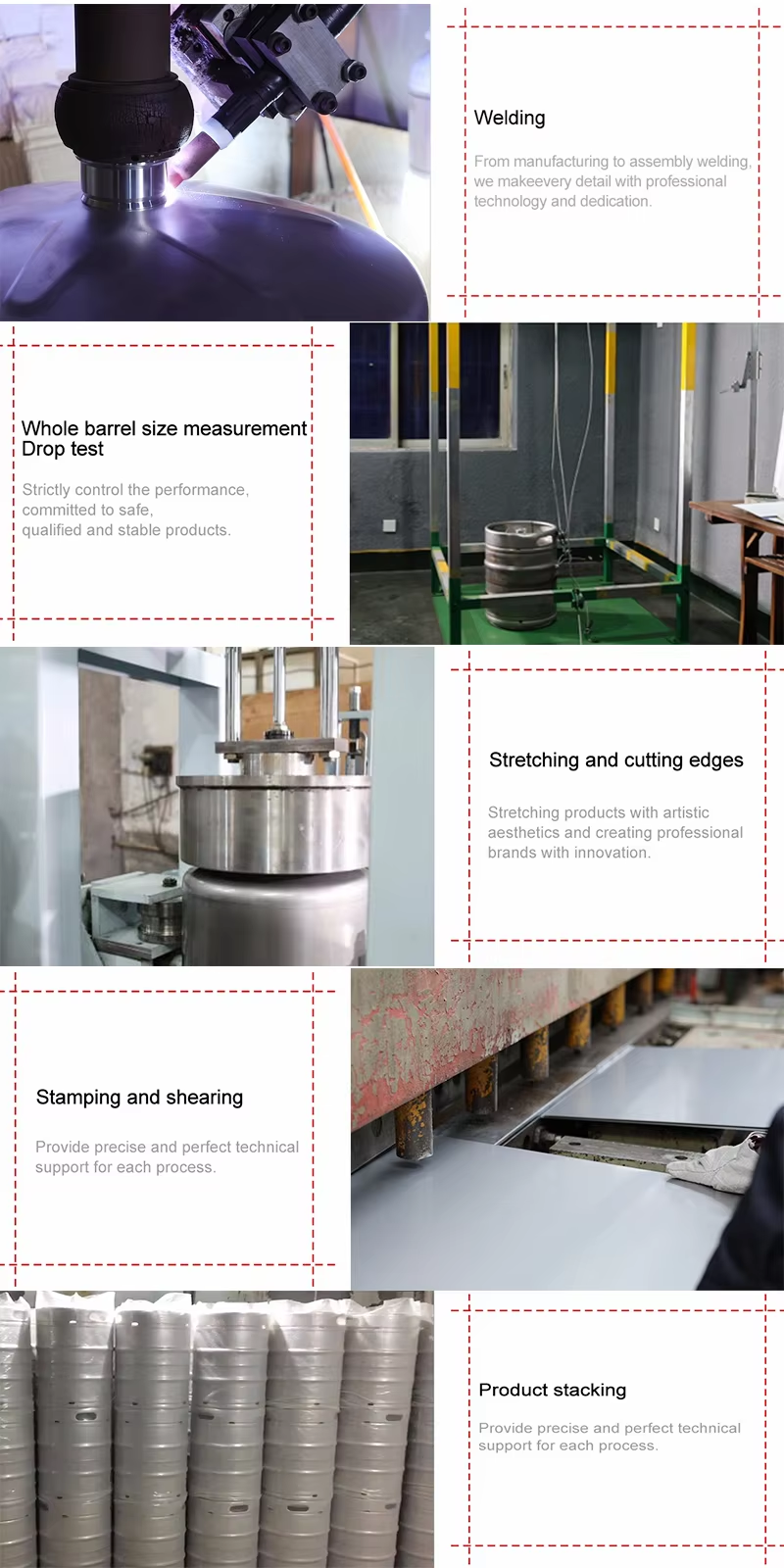

Production Process

1 Deep drawing: Special drawing presses are used to produce highly accurate, precision-dimensioned, smooth-surfaced deep-drawn parts from circular blanks.

2 Forming: Technical crimping of beads in the cold-formed keg halves. Cutting the keg halves. Making the bunghole in to half of the keg.

3 Welding in the necks: The necks are automatically welded in the top keg halves using a special method.

4 Embossing and labeling: Customer-specific data are embossed or stamped on the kegs in a special press. Such data include the customer’s name, logo, type approvals and serial numbers

5 From bending, welding, rolling: The chime strips are rolled into rounds, tensed and welded fully automatically to produce the chime rings. These are rolled in a hydraulic forming press equipped with special tools.

6 Stamping and forming: The hand and drain holes are stamped and punched fully automatically by precision machines. All parts are mechanically deburred safe handling.

7 Welding the chimes on the keg halves: The chimes are welded on the top and bottom keg halves by special welding methods.

8 Circumferential welding of the two keg halves: The keg halves are welded together to obtain the complete keg on fully automatic circumferential welding machines. Hygienic, smooth, narrow, flat weld seams and perfect weld root, especially on the side in contact with the product.

9 Pickling, pre-rinsing, passivation, rinsing: The kegs are pickled, rinsed and passivated inside and out, to ensure a grease-free, hygienically sealed surface.

Materia

SUS304/2B, the thickness is using 1.2mm, 1.5mm, 18mm, 2.0mm according to the capacity and customer’s requirements.

5. The pressure test

The keg is pressed with 0.5MPa and kept 3 minutes.

Warm tips :

1. Hand wash recommended with warm water & mild soap before first & subsequent uses.

2. Do not use bleach or abrasive cleaners.

3. Use only non-metallic bottle brush or preferably a bottle sponge.

4. Let dry thoroughly between uses and store with lid open.

5. Do not microwave or freeze.

6. Not designed for hot liquids, nonfood, or caustic, highly acidic materials.

7. Use for conditioning or fermenting at own risk.

8. Keep silicone seal away from young children.

.jpg)

Get A Quote