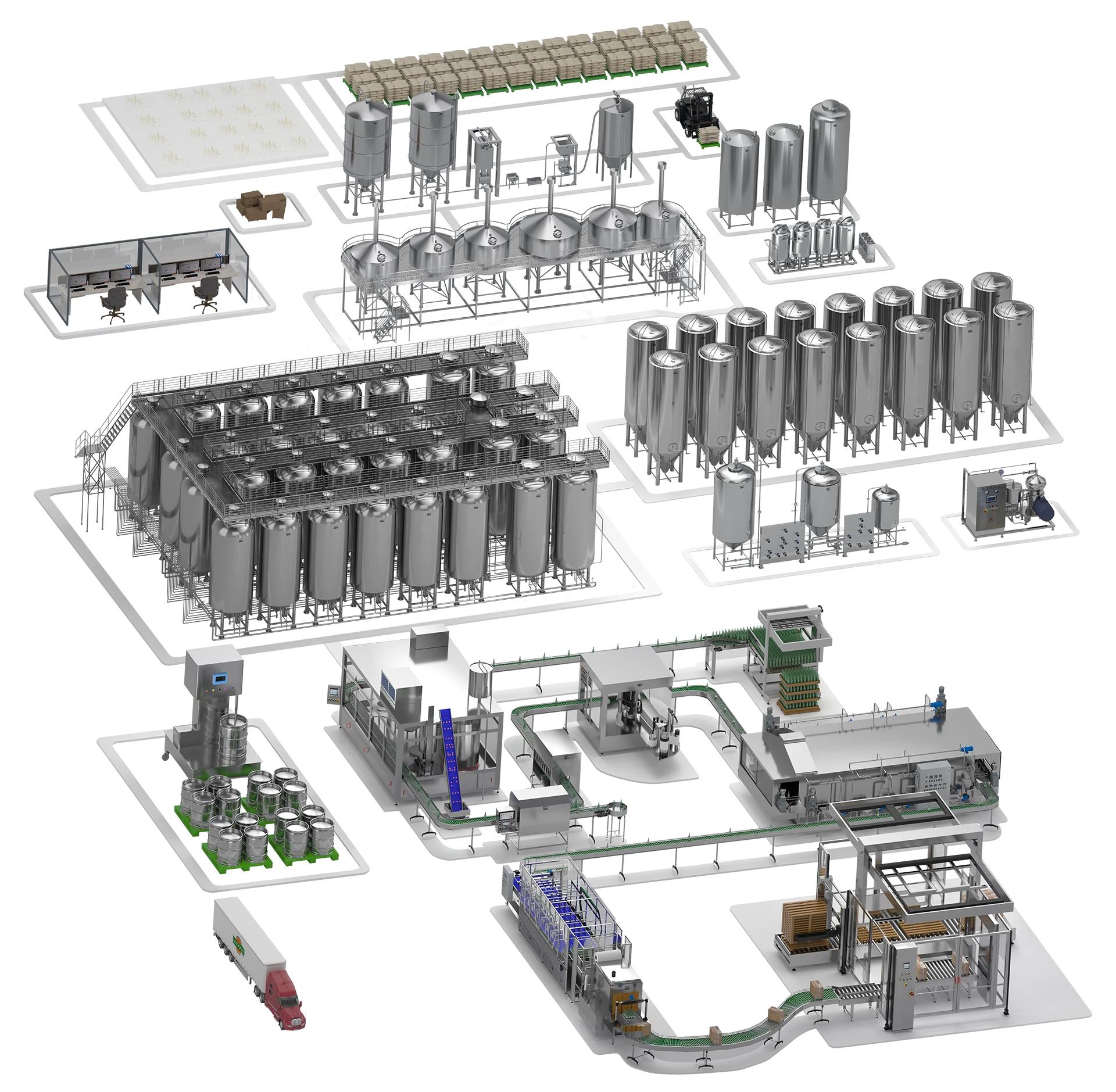

Are you ready to elevate your system to a new level? Our 7bbl brewery system is engineered for craft brewers looking to scale up production from small size craft brewing. This versatile system is ideal for expanding of small breweries, brewpubs, or experimental batches in larger operations. We offer turnkey solutions and comprehensive support from designing, customization to installation and maintenance and upgrades later.

Let’s take a look at the configuration details!

Normally the configurations included in standard 7bbl brewery system are:

Malt Mill with working capacity of 300-500kg/hr

[different model(carbon steel or stainless steel), flexible auger and controlling cabinet option available]

7bbl 2 vessel brewhouse

[mash/lauter tun, kettle/whirlpool tun and hot water tank;

Non-slip work platform(different styles);

Sanitary centrifugal pumps and piping, valves and fittings;

Manual water mixing station, manual wort cooling station;

Pipeline instrument sensor;

10L glass wort grant;

8m2 plate heat exchanger(double stage and single stage available);

Wort aeration station;

20L yeast feeder]

The brewhouse layout is available to be designed based on floor plan or dimensions requested, tanks dimensions available to be micro adjusted if there are room ceiling heights or space constrains. All tanks are equipped with adjustable foot pad for adjusting on floors.

Fermentation tanks

7bbl fermenter and brite tanks

Carb stone, bunging valves, level indicators, manway position provided.

Glycol Cooling System

14bbl glycol water tank, 5HP chillers, connection pipelines.

Electrical Control Cabinet

Brewhouse control and fermentation control

100L Portable CIP Cart

Heating source:

There are steam, electricity, gas fire heating way available to be configured based on personal requirements.

FAQ:

Q1: How long would I receive the cargoes after ordering?

A1: There are mainly three phases before the equipment arrived to your

door:

1) Drawings Prepared: once the order is produced, our engineers will designed the technical drawings for you asap., and then our

factory will manufacture the equipment for you exactly based on the drawings, this would be need about 7-14 days.

2) Manufacturing: the production, testing and final finishing of the complete system would be need about 60-70 days.

3) Vessel Booking and Shipment Arranging: 7 days around.

Q2: Do you offer installation or training services?

A2: Yes engineers are available to be send to your location to help with installation or training if needed.

Q3: How do I get the replacement accessories in the future? Are they available to be found in local store?

A3: Yes most of accessories we used are most likely to be found on international stores, if not, under the circumstances that they

are not in urgent uses, we'd love to resend them to you whenever there are needs.

Life long after sales services are provided.

Local installation services available to be provided if required, just feel free to let us know your preferred ideas and we’d do all we can to support.

Please feel free to send us an email or give us a call for a quote or more interested information, Cheers!

Sharon

E: [email protected]

Wapp/Phone: 86 183 0644 2562

Tiantai Brewery Equipment Company

.jpg)

Get A Quote