Among all brewery equipment solutions, mirror-finished tanks have always been a popular choice among customers for pursuing aesthetic appealing visions.

The term "mirror finish" refers to the high level of polish applied to the interior and/or exterior surfaces of the fermenter. This process involves multiple stages of grinding, polishing, and buffing to create a surface with a high degree of reflectivity and smoothness.

Key Features of Mirror Finished Beer Fermenters

Professional Look: The high-gloss finish provides a sleek and modern appearance, enhancing the overall look of the brewery.

Brand Image: Reflects a commitment to quality and attention to detail, reinforcing the brewery's brand image.

Improved Sanitation

Smooth Surface: The polished surface reduces microscopic crevices where bacteria and contaminants can hide, making the fermenter easier to clean and sanitize.

Hygienic: Enhances the overall hygiene of the brewing process, reducing the risk of contamination.

Durability

Corrosion Resistance: The high-quality stainless steel and polished finish enhance the tank's resistance to corrosion, extending its lifespan.

Scratch Resistance: The smooth finish is less prone to scratches and dents, maintaining its appearance and functionality over time.

Enhanced Performance

Efficient Cleaning: The mirror finish facilitates quicker and more effective cleaning, saving time and labor costs.

Temperature Control: The reflective surface can contribute to more efficient temperature management, crucial for consistent fermentation results.

Advantages of Mirror Finished Beer Fermenters

Superior Quality

Mirror finished fermenters are built to the highest standards, ensuring reliable performance and longevity.

Easier Maintenance

The smooth, non-porous surface makes maintenance straightforward, reducing downtime and keeping the production process running smoothly.

Improved Product Quality

Enhanced sanitation and temperature control contribute to producing higher quality beer with fewer risks of off-flavors or spoilage.

Cost Efficiency

While the initial investment might be higher, the long-term benefits of durability, reduced maintenance, and improved efficiency can result in cost savings.

Brewhouse with customized brewery logo.

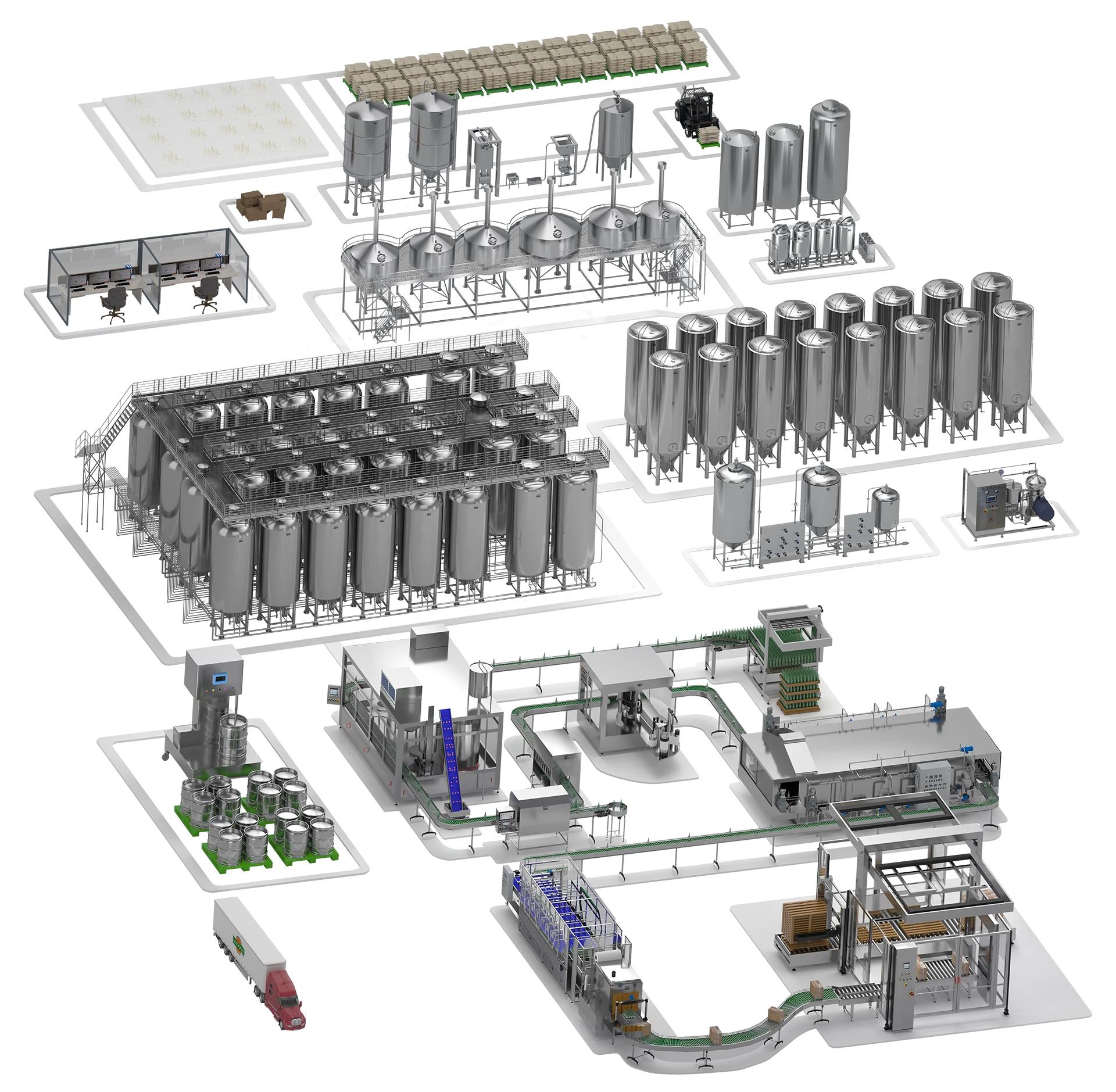

Applications of Mirror Finished Beer Fermenters

Craft Breweries: Ideal for breweries that prioritize both functionality and appearance, reflecting their artisanal approach.

Commercial Breweries: Suitable for larger operations where hygiene, efficiency, and durability are paramount.

Pilot Breweries: Perfect for experimental and small-batch brewing, where precise control and ease of cleaning are critical.

For more interested equipment details, just feel free to reach back to us anytime at your conveniences, our team would always be here ready for help!

E: [email protected]

Sharon

Tiantai Company

.jpg)

Get A Quote