A 6000L commercial brewery system is ideal for established microbreweries expanding into regional distribution or startups targeting high-volume output. This article we’d like to break down the system’s core components and characteristics of Tiantai 5000L brewery system, hope to help you have a clearer idea of the system combination and some main points to be considered. Any questions for related details please don’t hesitate to reach out, we are here ready for help!

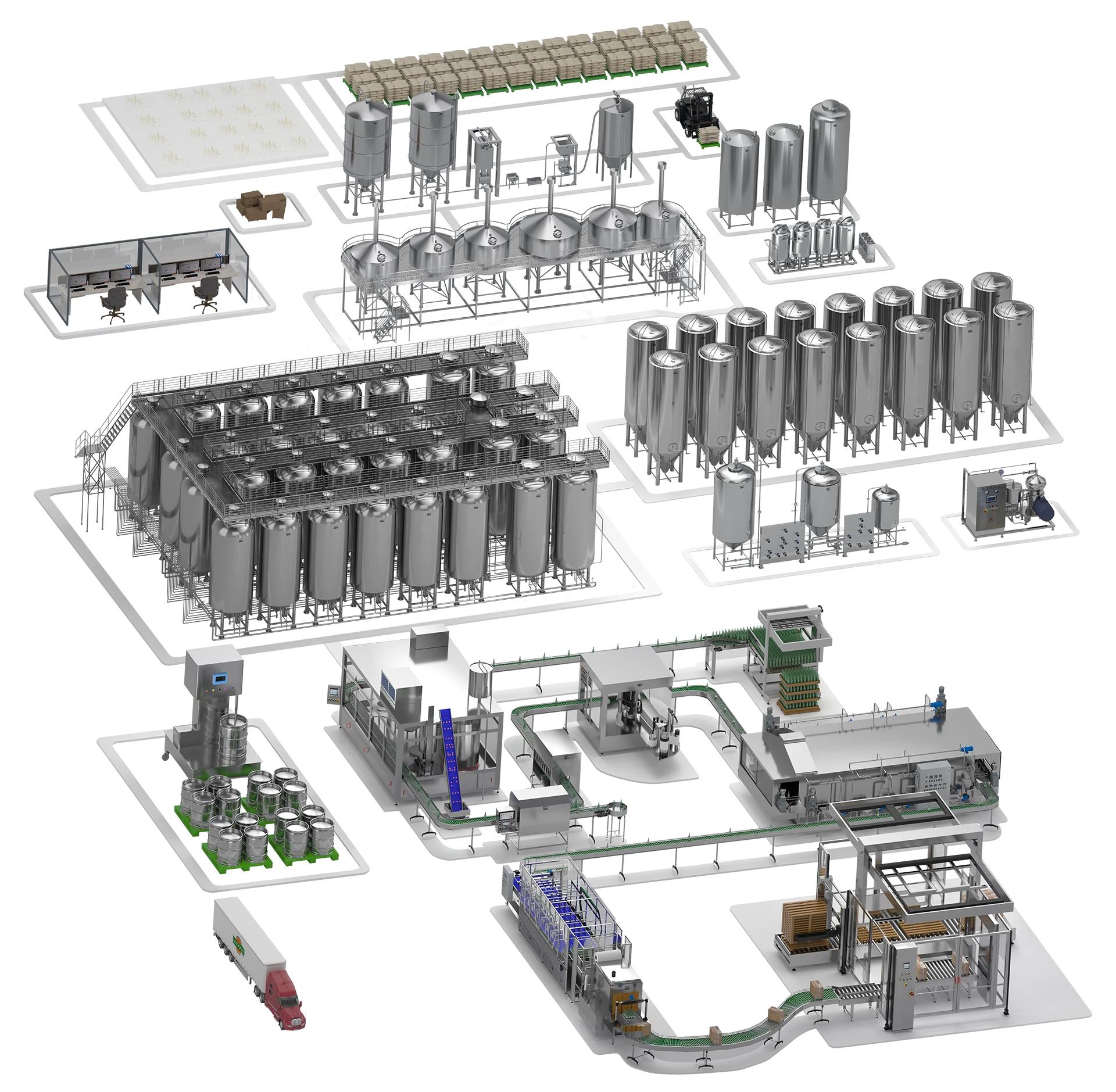

Key Components of a 6000L Commercial Brewery System

1. 3 Vessel/4 Vessel/5 Vessel Brewhouse

A 3/4/5-vessel brewhouse optimizes large scale brewing by separating mashing, lautering, and boiling into dedicated vessels. This design increases efficiency, reduces downtime, and ensures precise temperature control for consistent batches.

Different layout designed based on operational preferences or floor plan characteristics, and configurations customized available according to brewing requirements.

2. High-Capacity Malt Milling

Malt mill system including malt milling machine, flexible auger, grist silo and controlling cabinet. Industrial-grade malt mills with adjustable rollers process large volumes of grain quickly while preserving husk integrity. Integrated dust collction systems maintain a clean workspace, critical for compliance with food safety standards.

3. Conical Fermenters&Brite Tanks

Stainless steel fermenters feature dual-stage cooling jackets for precise temperature control during fermentation. Brite tanks allow for carbonation, conditioning and serving directly from the tank, streamlining workflows for kegging or canning lines.

4. Advanced Glycol Cooling System

A commercial-grade glycol chiller supports multiple fermenter and brite tanks simultaneously. Redundant compressors ensure reliability, while automated temperature logging guarantees consistency for lagers, IPAs, and hybrid styles.

5. Automated CIP Cleaning System

Industrial CIP units use programmable cycles to clean tanks, piping and heat exchangers. High-pressure spray balls and food-grade chemicals reduce labor costs and contamination risks in large systems.

6. Other Auxiliary Components

*Plate Heat Exchanger

*Steam Generator

*Control Cabinet

*Canning System, bottling system, kegging system.

A 6000L commercial brewery system is a transformative investment for brewers ready to scale. We offer a free consultation to analyze a brewery’s current output and demonstrate how a 6000L system aligns with your goals, feel free to reach out for any interested ideas:

E: [email protected]

Sharon

Tiantai Company

Get A Quote