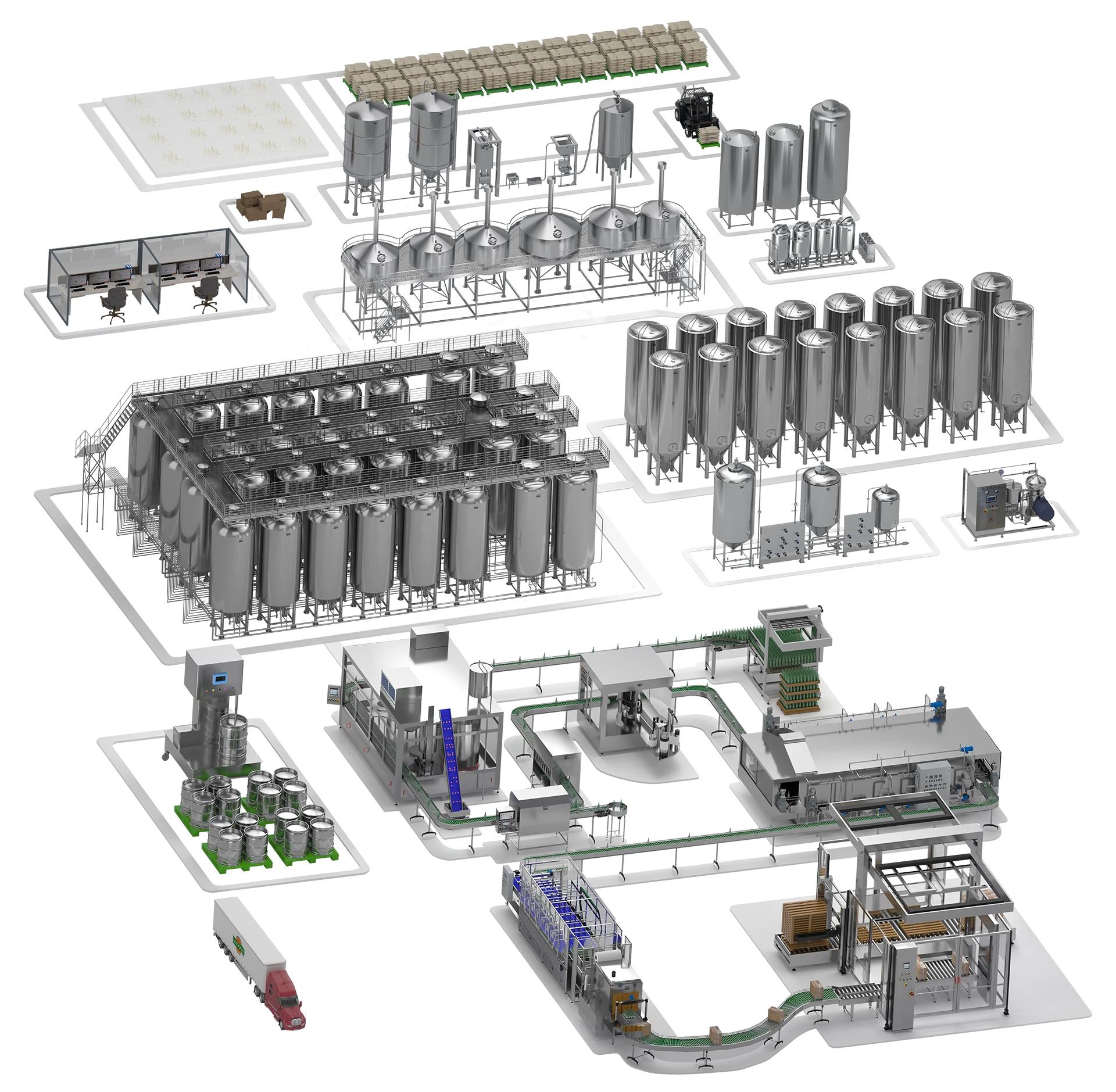

10,000KL Annual output Industry Brewery Project Solution

Brief Introduction:

Tiantai offers a wide choice of industrial brewery equipment and technology to customers at an optimal cost. Brewery equipment configuration is designed keeping in mind the raw materials, capacity and brewing profile of different brands. The process automation and control philosophy is developed to match volumes, efficiency and consistency of the final product. Our breweries comply with the latest and stringent international standards.

Configuration of 10,000KL Industrial Brewery:

Part 1: Silo Storage System

The main grain raw materials in a brewery include malted barley, wheat malt, rice flour, and others. The storage and transportation of malt can be achieved with either flat storage or vertical silos. Flat storage is mainly suitable for bagged packaging and is used by smaller breweries with a relatively low storage capacity. In comparison, silos are more suitable for bulk materials and offer larger storage capacities. Generally, the storage of various types of malt and auxiliary materials in a brewery should meet the demand for 10-30 days of use. The silo system not only satisfies storage needs but also enables automatic feeding, reducing labor costs.

Part 2: Malt Crushing System

The wet milling system is employed for malt crushing. The malt is first subjected to stone and iron removal processes to eliminate impurities that could affect the normal operation of the equipment. Afterward, it is mixed with 50℃ mash water and soaked for 15-20 minutes, allowing the moisture content of the malt to reach 30%. Then, the malt enters a roller mill for crushing. During the crushing process, mash water is used to adjust the slurry. Wet milling is particularly suitable for brewing systems that involve high input quantities and continuous production.

Part3: Brewhouse System

The mashing system is one of the most critical components of beer production equipment. Its design must align with the mashing process to ensure high-quality wort, which directly impacts beer fermentation, filtration performance, and the final beer flavor. The mashing process primarily includes gelatinization, saccharification, wort filtration, boiling, whirlpooling, and wort cooling.

The design of the mashing system requires strict control of key production parameters, such as mashing temperature, mashing time, wort concentration, and pH value. The wort filtration system must ensure maximum clarity while optimizing production efficiency and extract yield. It should effectively separate soluble extract from the mash while minimizing unwanted compounds that could affect beer flavor.

During the boiling stage, hops are added in batches, and modern wort boiling technology is used to maximize heating efficiency and energy savings while volatilizing unwanted compounds like DMS (Dimethyl Sulfide). After boiling, the whirlpool tank separates hot coagulated solids and hop residues from the wort, ensuring clarity. The wort is then cooled to fermentation temperature using a plate heat exchanger, where oxygen is introduced to support yeast growth and reproduction.

The main equipment in the mashing system typically includes a gelatinization tank, mashing tank, lauter tun or mash filter, wort boiling kettle, whirlpool tank, plate heat exchanger, Venturi oxygenation system, and yeast addition system. The mashing system is designed based on modern brewing technology and tailored to the diverse needs of craft beer production, ensuring precise process control, improved production efficiency, and optimal raw material and energy cost savings.

Part 4: Fermentation System

Fermentation is an extremely important process in beer production, in which yeast participates in complex biochemical reactions. Fermentation generally uses indoor or outdoor cylindrical cone-bottom fermenters, which are equipped with automatic cooling systems and can easily control the fermentation temperature. The cone-shaped tank bottom is convenient for yeast recovery. The CIP cleaning device can achieve all-round cleaning and sterilization without dead ends, ensuring the hygiene and safety of the production process. Fermentation tanks of different specifications and quantities are configured according to factors such as the fermentation cycle of different types of beer, the production proportion of different types of beer, and brewing batches.

Part 5: Yeast Propagation System

The yeast expansion system expands and cultivates the pure yeast stored in the brewery, and after reaching a certain number of yeast, it is available for use on the production site. The yeast expansion system can realize the independent production of yeast in the brewery, which can more effectively ensure the purity of yeast and stabilize the quality of yeast, thereby achieving stable beer quality. Yeast expansion is separated by laboratory cultivation, and after Karlsruhe jar cultivation, Hansen jar cultivation, and expansion cultivation, it enters the yeast storage tank and is finally used in the beer fermentation tank. The yeast expansion system is suitable for breweries with large production, professional teams and test equipment.

Part 6: Centrifugal Filtration System

Disc centrifuges are mainly used for beer separation. High-speed centrifuges can greatly remove yeast from beer to increase the clarity of beer and reduce yeast precipitation. It is especially suitable for brewing wheat beer. Centrifugal technology has extended the shelf life of beer to a certain extent, while also ensuring the freshness of beer. It is usually suitable for fresh beer circulated in the cold chain. It can also be used in conjunction with instant sterilization to further extend the shelf life of beer. High-quality centrifuges must control oxygenation below 5-10ppb.

Part 7: DE Filtration System

The candle-type diatomaceous earth filtration system is one of the most commonly used filtration methods in beer. The filtration system is mainly based on candle-type filters, equipped with a series of auxiliary equipment, such as front and rear buffer tanks, soil mixing and adding tanks, head and tail tanks, and corresponding pipes, valves, detection sensors, etc. The candle-type diatomaceous earth filter is mainly composed of many vertical candle wicks. The filter aid (diatomaceous earth) is attached to the outside of the filter element after pre-coating, second and third pre-coating. The filter aid is continuously added through the soil mixing and adding system. After pre-coating, it can effectively filter yeast, condensation sediments, etc. in the beer, making the beer clearer.

Part 8: Bright Beer System

The bright beer system is used to receive beer liquid after filtration or other process treatment, and is used as a pre-filling storage tank for carbonization before filling. It can also be used as a beer storage system after beer fermentation. The main equipment is different specifications of sake tanks and corresponding pipeline systems. The specifications and quantity of sake tanks are equipped according to the production capacity of fermentation tanks and filling systems. Fully consider the influencing factors such as the type of beer filling and the proportion of different types of beer.

Part9: Beer instant sterilization

Instant sterilization is used before filling, using high-temperature steam to heat the beer for a short time of 35-40 seconds to achieve the sterilization effect. After heating, the temperature is quickly cooled to retain the beer flavor to the greatest extent and reduce the aging taste of beer. Strict aseptic filling is often used after instant sterilization. Instant sterilization is often used in the production of fresh beer.

Part 10: High-concentration dilution system

Among all types of beer consumption, light beer has always been favored by the market. High-concentration dilution technology is one of the important innovations in the production of light beer. It is necessary to ensure that the beer has a solid flavor and a stable body, and there must not be problems such as bland taste, coarse foam, poor foam retention, reduced killing power, reduced color, poor body coordination, and poor non-biological stability. This puts higher requirements on the design and manufacture of high-concentration dilution equipment. Tiantai's specially designed mixing structure and carbon dioxide cutter allow the wine to fully contact with carbon dioxide molecules, and at the same time continuously change from laminar flow to runoff and turbulent flow, which improves the dissolution effect of wine, water, carbon dioxide additives and other ingredients in the wine. The mixer in the pipeline increases the wine's mouth-watering power when diluted at a large proportion under the action of the pressure-holding pipeline, ensuring that the diluted wine meets the requirements. The system is equipped with a precise carbon dioxide metering system, which can successfully control the carbon dioxide content in the diluted finished wine and solve the problem of unstable carbon dioxide.

Part 11: Control System

The brewery automation system is the most critical part in the modern beer brewing production process. It includes automatic control system, monitoring system and data analysis system.

Part 12: CIP System

The CIP system is an essential cleaning equipment in the brewery configuration. Compared with most beverages, the brewing of beer has more stringent hygiene requirements, and any minor hygiene problems may cause contamination of the entire batch of products. Through a reasonable and comprehensive CIP system configuration, the tanks, pipes, etc. can be effectively cleaned and sterilized to ensure the hygiene of the brewing process and the stability of beer quality. Each section of a modern beer factory will be equipped with an independent CIP system, such as the crushing workshop and wort saccharification workshop, the wort to fermentation tank pipeline and fermentation tank workshop, the yeast expansion workshop, the sake and filtration workshop, the filling workshop, etc. The cleaning process used in different sections is also different.

Part 13: Concentrated Acid And Alkali Addition System

The concentrated acid and alkali addition system is used to add acid, alkali and disinfectant to the CIP system. Because concentrated acid and alkali are dangerous chemicals, there are certain safety hazards when adding them manually. The addition system can achieve unmanned and automatic addition, and the addition process is completed in a closed pipeline, which can avoid safety issues for personnel.

Part: 14: Public Water System

Hot water supply system

Cold water supply system

Brew water supply system

Glycol water supply system

Deoxygenated water supply system

Part 15: Public Supporting System

Glycol chilling system

RO water system

Steam supply system

Compressed air supply system

CO2 supply system

CO2 recovery system

Electric power communication system

Part 16: Filling and Packaging System

Keg filling system

Can filling system

Bottle filling system

More details, please contact Abby

Email: [email protected]

Whatsapp: +86 170 9164 4622

.jpg)

Get A Quote