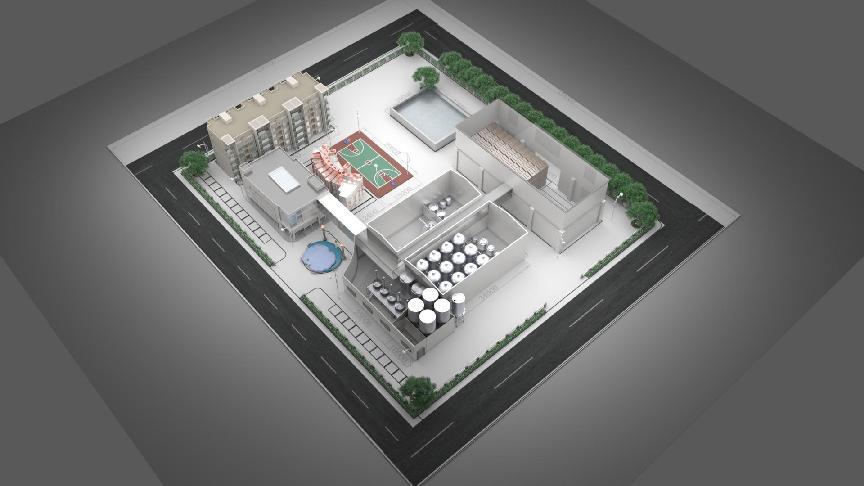

Just like the essential role of fermentation tanks in a brewery, the glycol cooling system is also necessary for maintaining precise temperature control during various stages of beer production, especially fermentation and conditioning as well as the wort cooling.

Her are main components suggested in cooling system for large size of commercial breweries:(Take 2000l brewery system as example)

1. Glycol Water Tank

To provide glycol water supply for Fermenters, Brite Beer Tank, Cold Liquor Tank or wort cooling, the size of Glycol Water Tank suggested for 2000l brewery system is usually 2000L. The tank is designed with 2000l working capacity and with minimum of 15% headspace. Empty level switch provided as optional.

| Specifications | |

| Tank Capacity | 2000L (15% Headspace) |

| Function | Glycol Water Supply |

| Dimension | 1360*2515mm |

| Cooling Jacket | No |

| Insulation | TH 80mm Low Thermal Conductivity PU |

| Manhole | Stainless Steel Manhole Top Mounted |

| Main Components | Sanitary Thermowell, Breath Port, Glycol In and Outlet, Drainage Port, Discharge Arm |

2. Cold Liquor Tank

To provide enough and timely cooling capacities for wort cooling, especially with multiple batches of continuous productions, 4000L cold liquor tank is suggested in the 2000l brewery system. Cooling jacket and 80mm insulation equipped for bottom cone, down and upper part of side wall. Empty level switch and pressure transmitter provided for options.

| Specifications | |

| Tank Capacity | 4000L (+15% Headspace) |

| Function | Cold Water Supply |

| Dimension | 1860*3000mm |

| Cooling Jacket | Dimple Jacket on Side Wall and Bottom |

| Insulation | TH 80mm Low Thermal Conductivity PU |

| Bottom | Conical |

| Manhole | Stainless Steel Manhole Top Mounted |

| Main Components | 360°Rotary CIP Spraying Ball, Sanitary Thermowell, Floating Ball Low Level Sensor, Breath Port, CIP Inlet, Overflow Port, Drainage Port, Discharge Arm |

3. 8HP Chiller

| Specifications | |

| Function | Glycol Water Chilling |

| Type | Air Cooled Glycol Water Chiller |

| Horsepower | 8 HP |

| Cooling Capacity | 11000 W/9500 Kcal/Hr |

| Installed Power | 7.8 KW |

| Size | 1505*720*13250mm |

| Weight | 265KG |

4. Glycol Water Pipelines

Function: Glycol Water Circulation

Mainly Including:

1) 1pc Glycol Water Pump 1.5kw 8M3/HR H=35m;

2) 1pc Cold Water Pump: 15M3/Hr, Sanitary 304SS, delivery 24m

3) 304SS Solenoid valve DC24V for each tank (Angle Seat Valve for special request)

4) PPR pipes and fittings between GWT and GW pump

5) PPR pipes and fittings from GW Pump to tank inlet components

6) PPR pipes and fittings from tank outlet components to GWT

7) PPR pipes and fittings between chiller and GWT

8) PPR pipes and fittings for tank inlet components including solenoid valves

9) PPR pipes and fittings for tank outlet components

10) Rubber foam Insulation for supply and return loops

11) Site installation instruction service included

12) All pipe and fittings calculated by layout with 10% allowance

13) 6 Temperature controlling points as standard

Feel free to reach to us to get a free quote or any more interested details:

E: [email protected]

Cheers!

Tiantai---Your Honest Brewery Equipment Builder!

.jpg)

Get A Quote