Just like the essential role of fermentation tanks in a brewery, the glycol cooling system is also necessary for maintaining precise temperature control during various stages of beer production, especially fermentation and conditioning as well as the wort cooling.

Main components included in glycol cooling system:

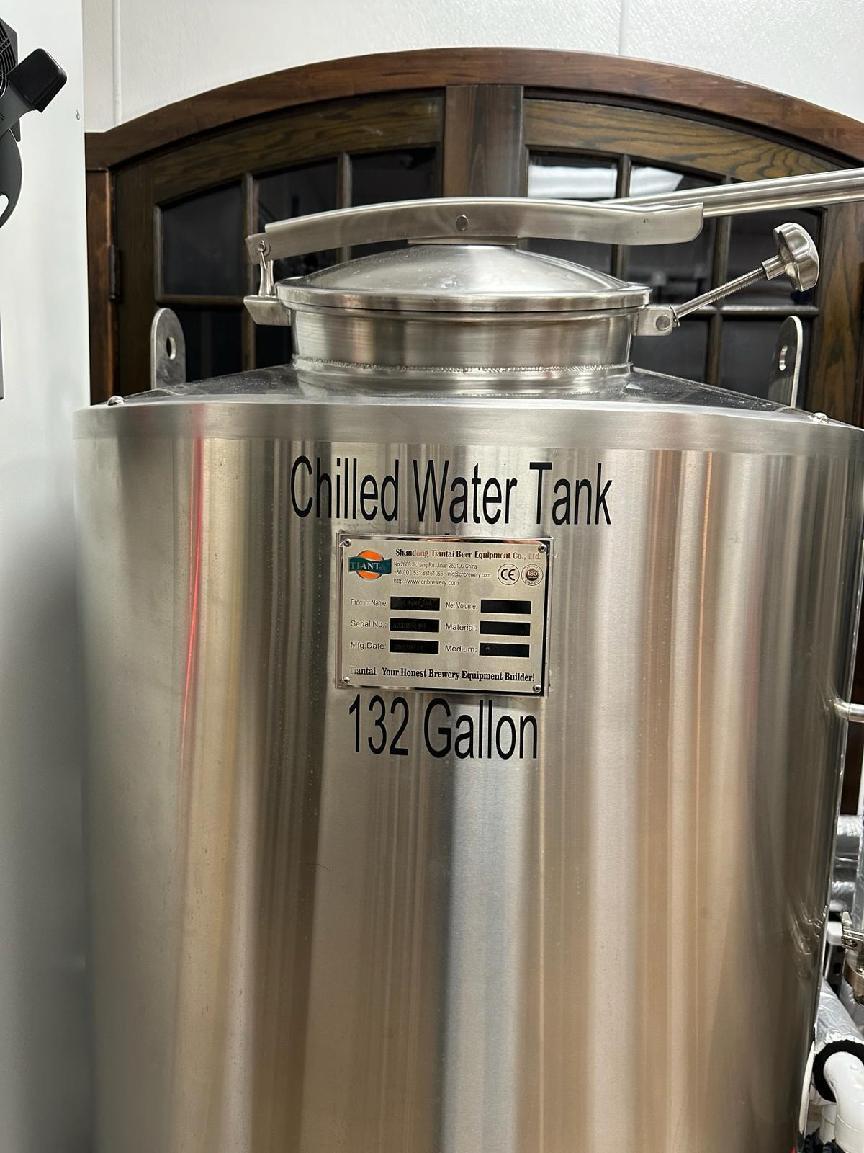

1. Glycol Water Tank

The size of glycol water tank are usually suggested to be the double size of the brewing vessels considering to provide timely and enough cooling capacity for the brewing needs. Like in a 500l brewhouse system, 1000l glycol water tank would be kindly suggested, but if there are other factors to be considered like space or budget limit, the size is available to be customized based on preferences.

| GWT Specifications (500L Brewery) | |

| Capacity | 1000L (15% Headspace Minimum) |

| Dimension | Φ1260×1860mm |

| Interior Shell | SUS with TH 3mm |

| Exterior Shell | SUS with TH 2mm |

| Insulation | TH 80mm with Lo Thermal Conductivity PU |

| Working Pressure | Atmosphere |

| Bottom | Conical |

| Temperature Sensor | Included |

| Tank Foot | Heavy Adjustable Foot Pad |

2. Chillers

The chillers we’ve been cooperated with is belong to our government-worked brand---Kansa. Both quality and working performance are ensured.

As for the number of chillers, usually two sets would be kindly suggested first considering mainly two factors:

1) Energy Saving: it can be decided flexibly whether to use one or two sets of chillers together depends on different situations. For example, when there are large demands for cooling capacities like both the wort and all fermentation tanks need to be cooled down at same time, it would be better to let the two chillers working together to make sure the cooling job down efficiently; And when the cooling demands is small like only one or two fermenters need to be cooled, one chiller would be enough to do the job. Therefore, take a 500l brewing system as example, usually two sets of 3HP chillers would be kindly suggested instead of one set of 5HP chiller if space allows.

2) Emergencies: two sets of chillers help to reduce the risks of some special occasions like one chiller break down or fail to work for some other reasons. This would effectively help to avoid the risk of beer losses.

3. Pipelines&Transfer

All pipelines needed for the connection including solenoid valves will all be offered, mainly including:

| Pipeline Specifications(500L Brewery) | |

| Glycol Water Pump | 0.75kw 4M3/Hr H=31m |

| Temp Control | 6 Temperature Controlling Points as Standard |

| GWT to Pump | PPR Pipes and Fittings |

| Pump to Tanks | PPR Pipes and Fittings |

| Chillers to GWT | PPR Pipes and Fittings |

| Solenoid Valves | Included |

| Special Request | Stainless or UPVC Pipeline Provided for Options |

Tailored brewing system supplied to meet different requirements, feel free to reach to us if there are any needs please, we are happy to be any helps!

Thanks a lot for your attention and all the best wishes with brewing business!

Cheers&Best Regards,

Sharon

E: [email protected]

Tiantai---Your Honest Brewery Equipment Manufacturer!

.jpg)

Get A Quote