Here is Tiantai Beer Equipment Co., Ltd.

Welcome to visit our brewery equipment website!

Please allow me to share this 100L Portable CIP Cart with you.

The full name of the CIP is Cleaning In Place. It is usually being used in craft breweries to conduct cleaning mission for fermenters or sometimes the heat exchanger.

The control panel is also can be customized into a completely stainless steel one if you prefer.

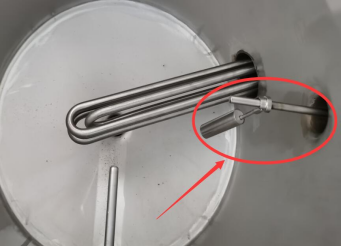

This is an anti-dry burning device inside the caustic tank, it is used for protecting the heating elements when the caustic liquid is not enough. Specifically, when the level of the caustic liquid is lower than the normal position, this anti-dry device will send an alarming signal to the control panel, so the control panel will stop the tank from working and the warning light on the control panel will be turned on to cause your attention.

How to choose the suitable size of your CIP system?

It depends on the size of your fermentation tanks (including BBT). Normally, the size of the CIP is 10% of the volume of your fermenter, for example the 100L CIP is usually suitable for fermenters less than 1500 litres.

The components of the 100L Portable CIP:

It mainly includes two tanks------Caustic Tank and Acid Tank; the Control Panel, Centrifugal Pump, Movable Cart and other fittings and valves.

Working Principle:

Preparatory Work:

First we fill 100L clean water into the caustic tank and the sterilization tank respectively and then add 5kg food grade caustic soda into the caustic tank to make the concentration of caustic liquid up to 2%-4%.

Next add about 100ml 35% hydrogen peroxide liquid into another tank, and mix the liquid to make a concentration of 300-400ppm.

Clean water washing for 15 minutes:

Wash the tanks with clean water, small amount of water with several times is better——usually 3 times and 5 minutes each time. Finally drain out the remaining water and do the next step, at the same time keep the discharge port of fermenter open.

Caustic washing

After draining out the remaining water in the fermenter, use the hot caustic liquid prepared in advance to wash the tank with several circulations for 15-20 minutes.

Or we can let the tank being steeped for 30 minutes.

At last, we need to use warm water to rinse the tank to clean, we can use these conditions to determine whether the tank is clean:

① The warm water is clear and clean;

② No suspended solids in water;

③ No special smell;

④ No foam and bubbles.

Attentions:

① The caustic liquid can be recycles to use several times until its condition is not good;

② It is extremely important to wear protective appliance like mask, gloves, leather boots, glasses, etc. during the process.

Because the caustic liquid is highly corrosive, please try to avoid directly contact with it.

This 100L Portable CIP Cart is designed to serve micro craft brewers for cleaning fermenters efficiently.

Other configurations and details to be discussed to meet your personal demands and special requests, we shall be honored to support you build your brewery dream in any way we can.

Welcome to contact me for more interested details and talk about pro brewing with us.

Cheers!

.jpg)

Edited by Sharon from Tiantai Brewery Equipment

Contact:[email protected]

.jpg)

Get A Quote