Hello there, welcome to visit our brewery equipment website!

This is Sharon here from Tiantai Brewery Equipment Company.

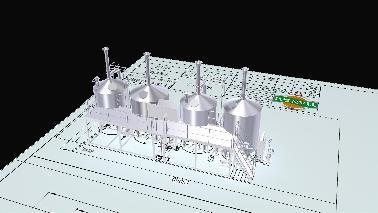

Here we’d like to share with you this turnkey brewing project of 5,000L commercial brewery system installed, it mainly includes a 4-vessel brewhouse with PLC controlling cabinet, 20,000L fermentation tanks&brite beer tanks, CIP cleaning system for both brewhouse and fermentation tanks, others like bottling line and keg machine, etc. If you are gathering some information for similar size of project or equipment to scale up your productions, feel free to reach us back anytime at your conveniences for more interested information please, Cheers!

Let’s discover the main procedures, configuration details and what services we provided during the whole process!

1. Brewery Layout Confirming.

Based on your floor plan draft drawing, our engineers would help to design the complete brewery layout with all factors considered including walls, room heights, pillars and all the other obstacles to make sure the system to be well fitted in your site in the future, which can also helps to confirm the specific configurations included in your system.

If the space is yet to be decided, we can also provide an initial layout with standard dimensions to help you locating the suitable place, and then it can always be updated based on your further requests like personal operational preferences, placing orders, etc.

2. Configurations Confirming.

The specific configurations included in the system will be suggested and confirmed based on your preferences and production goals.

-Usually there would be a 4-vessel brewhouse configured for this size of system to make sure continuous batches brewing per day, a 5-vessel brewhouse is also available to be customized to increase the output volumes if you like.

-Combination of different sizes of fermentation tanks like 20,000L and 10,000L to meet your beer types requests.

Main configurations suggested in the 5000L Brewery System:

| Part 1: Malt Milling Unit | |

| 1.1 | Malt Mill [2000-2500kg/hr] |

| 1.2 | Flexible Auger |

| 1.3 | 3500L Grist Silo |

| 1.4 | Milling Controling Cabinet |

| Part 2: 50HL Brewhouse | |

| 2.1 | 50HL Mash Tun |

| 2.2 | 50HL Lauter Tun |

| 2.3 | 50HL Brew Kettle |

| 2.4 | 50HL Whirlpool Tun |

| 2.5 | 100HL Hot Water Tank |

| 2.6 | Non-slip Work Platform |

| 2.7 | Sanitary Centrifugal Pump [LYSF] |

| 2.8 | Sanitary Piping |

| 2.9 | Valves and Fittings |

| 2.10 | Pipeline Instrument Sensor |

| 2.11 | Balance Column |

| 2.12 | 50M2 Heat Exchanger [304SS NANHUA] |

| 2.13 | Wort Aeration Station |

| 2.14 | 50L Yeast Feeder |

| Part 3: Fermentation Unit | |

| 3.1 | 20000L Fermentation Tank/Unitank |

| 3.2 | 10000L Fermentation Tank/Unitank |

| 3.3 | 20000L Bright Beer Tank |

| Part 4: Glycol Cooling Unit | |

| 4.1 | 5000L Glycol Water Tank |

| 4.2 | 10000L Cold Liquor Tank |

| 4.3 | 20HP Glycol Water Chiller |

| 4.4 | Glycol Water Pipeline |

| Part 5: Electric Control Unit | |

| 5.1 | Brewhouse Control Cabinet |

| 5.2 | Fermentation Control Cabinet |

| Part 6: 1000L Fixed CIP Unit [Three Tanks] | |

| 6.1 | 1000L Double Wall Caustic Tank |

| 6.2 | 1000L Single Wall Acid Tank |

| 6.3 | 1000L Single Wall Sterilized tank |

| 6.4 | Sanitary Centrifugal Pump |

| 6.5 | Sanitary Piping |

| 6.6 | Valves and Fittings |

| 6.7 | CIP Controling Cabinet |

3. Equipment Production.

Once the technical drawings confirmed, the factory would start the manufacturing immediately based on drawings exactly!

20,000L fermentation tanks and bbt produced outside.

Logos customized on glass manholes or tanks body based on requirements.

PLC control cabinet with Siemens touch panel.

Stainless steel manifold equipped for better liquid transferring and tubes cleaning.

2000L 4-vessel CIP Cleaning Station.

4. Testing and Inspecting.

After the production is completed, we’ll run a complete testing of the whole system before delivering to make sure the machine is working well.

5. Cargoes Delivering.

Shipping services provided to send the cargoes to your preferred picking-up locations like the nearest sea port from you, or door to door services.

6. Installation and Running.

Engineers are available to be sent to your location to help with installation and testing if you prefer. Otherwise all necessary materials will be provided to help if you’d prefer to do the installation yourself like technical drawings, manual instructions, photos and videos.

Premium quality, service excellence, and long-term customer satisfaction is what we've been focusing on and striving for like always,

If there are any new chanllenges or opportunities we might be able to serve you for your business or project, please don't hesitate to reach back at your conveniences for more interested information, we'd always be here ready to help!

Happy brewing and best luck of your business!

Sharon

E: [email protected]

.jpg)

Get A Quote