In Tiantai, the brewery equipment can customized to different needs of customers.

Here I want to share with you some basic specifications of a 500L beer brewing system which was delivered recently.

It’s a 3 vessel 500L brewhouse, Please check the picture as below:

1. 500L three vessel brewhouse [MT+ LT+ KWT]/HLT

The 500L three vessel brewhouse [MT+ LT+ KWT]/HLT can save more time when doing more than 2 batches per day.

This brewhouse was designed as steam heating and will be installed in a 40'HQ container.

2. Back flushing device with nozzles and wort collection ring installed under lauter tun.

The wort collection ring can make the wort lautering process more evenly and reduce the possibility of grainbed to be stuck, especially for high gravity beer.

And back flushing device can help cleaning the space under false bottom.

Many brewers like this design.

3. Wort grant

Wort grant is working as a buffer tank and can help wort lautering by gravity. In addition, it can also protect the false bottom and wort pump.

Some brewers also prefer equipping level sensor in it to make the wort pump working more automatically.

4. Pipe filter

Pipe filter which is equipped on pipeline before heat exchanger to help prevent hot trub go into heat exchanger.

For bigger breweries, two filters installed in parallel are more common.

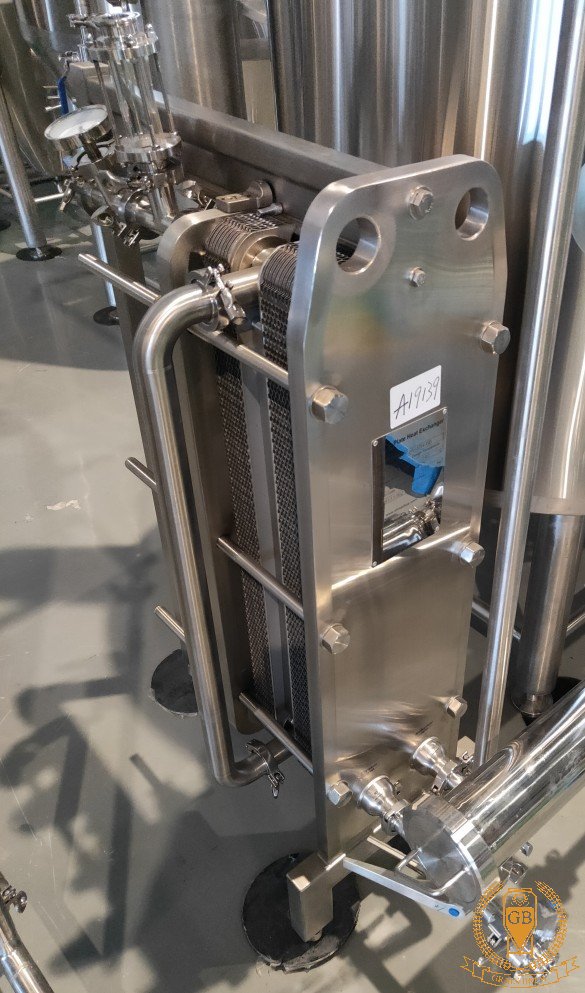

5. Heat exchanger

The heat exchanger is from Chinese top supplier, which has a high heat exchanging efficiency.

And it’s consists of hygiene grade SUS304 and EPDM gasket.

6. Water blending station with flow meter

The valves we use for mixing water are the diaphragm valves, it can regulate water flow linearly.

That helps to make the temperature and volume of hot water more accurate.

Are you interested in getting a quotation for your beer brewing equipment?

Drop Jane an email for further information!

E: [email protected]

Get A Quote