Grain brew is a manufacturer who only dedicate in manufacturing brewery brewhouse and tanks. We have big oversea customer base in different countries.

Thanks to our good customers. Their feedback and hand-on experience help to improve our design and quality to be better and better.

Here I will show our latest two updates about the beer brewing equipment design:

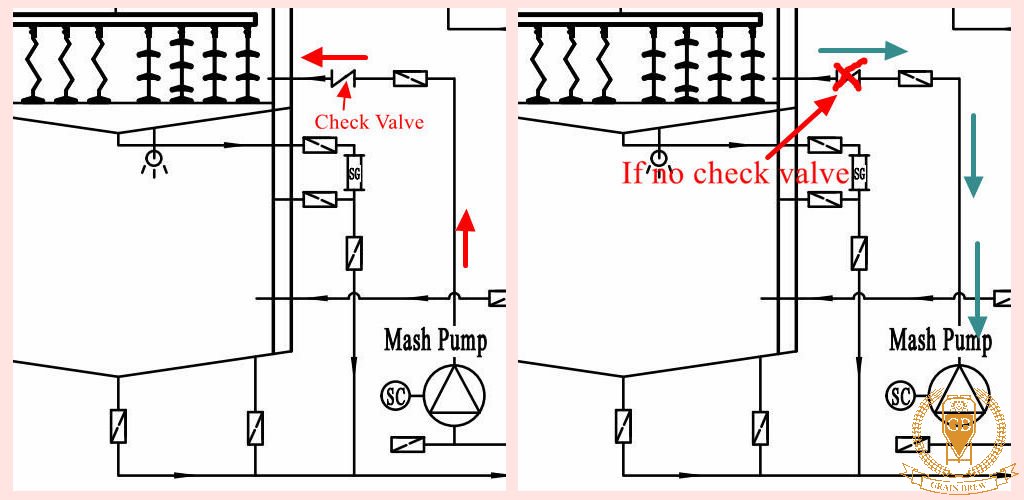

1. Check valve added on tanks' inlet

According to some customers' feedback, after the wort transferred to kettle tun, it is easily flowing back to a lower position in the pipeline if the inlet valve hasn't been closed timely after pump stop.

Like below pictures shows:

After getting the feedback, our engineers have been trying different solutions.

Finally the option of adding a check valve on the inlet was adopted. Then we installed it on some projects, and customers' feedback were positive.

Then it was set up as a standard specification on the system for all the inlets which are lower than the liquid level in tanks.

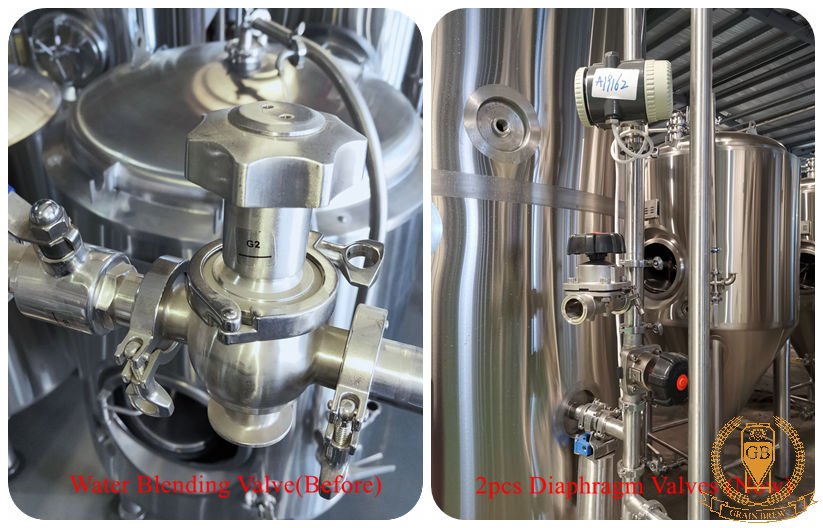

2. Diaphragm Valves for water blending station

For water blending station, before we were using a water mixing valve. According to customer's feedback, the mixing is not that ideal.

Then we tried to install two ball valves, one on city water line, another on hot water line. It was much better but the disadvantage of ball valves is that they are not linear.

The valves now changed to 2 sets of diaphragm valves as standard. They do better on flow control than ball valves and it's easier to reach the desired temperature.

Please check the below pictures about them:

Any open ideas are really welcomed.

Our approach: To facilitate the operation of brewers as much as possible and offer best quality equipment with the least amount of money!

Edit by Jane

E:[email protected]

Get A Quote