The fermentation tank is one of the important equipment in the beer brewing process. The beer fermentation process is the normal life activity of yeast under certain conditions, using the fermentable substances in the wort. Yeast will generate heat during the fermentation process. In order to make the fermentation and post-ripening proceed at the set process temperature, it must be cooled.

Two cooling methods:

Indirect cooling method: The cooling jacket passes through a mixture of ethanol or ethylene glycol and water (refrigerant).Direct cooling method: The refrigerant in the cooling jacket is liquid ammonia.

There are two commonly used cooling jacket methods in beer fermentation equipment, one is Miller plate and the other is coil.

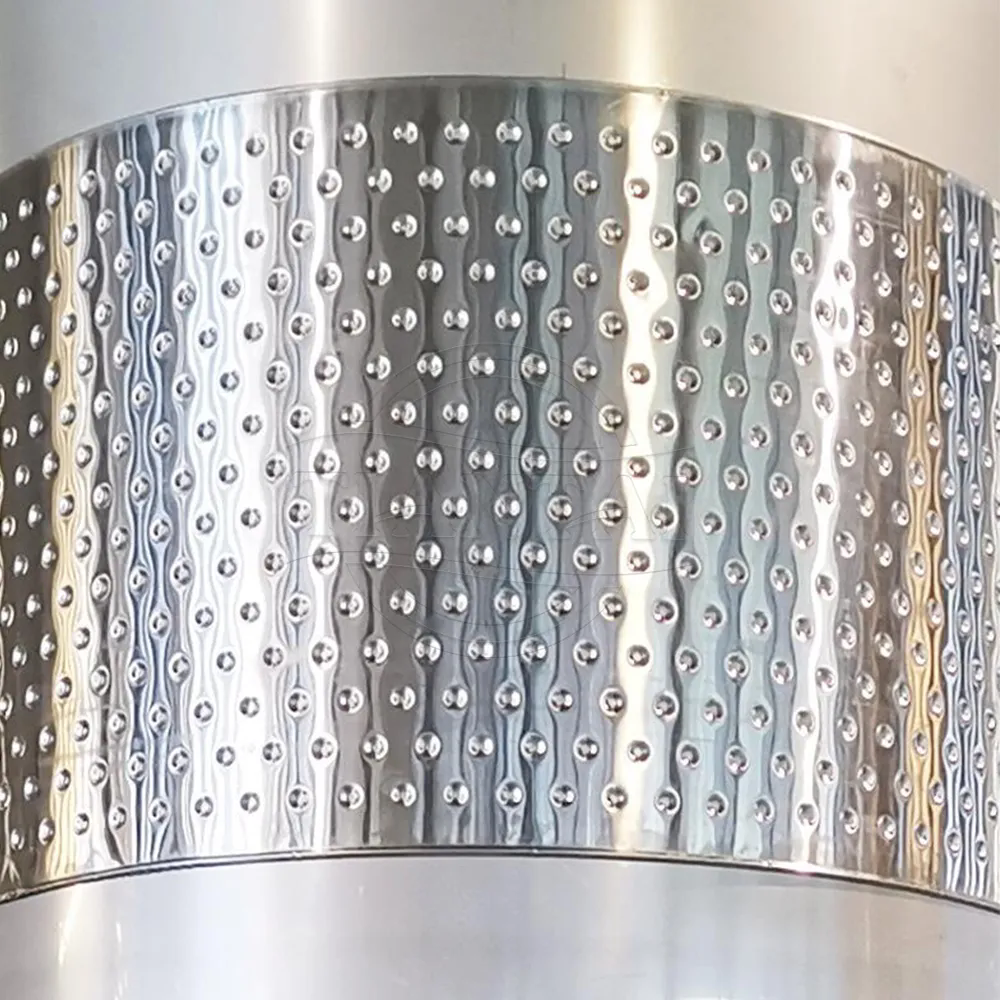

Jacket

Definition:

The jacket is made of two thin stainless steel plates, which are perforated and firmly bonded to both sides of a thicker honeycomb core material. It is also called a honeycomb sandwich structure. It has the characteristics of light weight, sound insulation, and good elasticity.

Function:

The function of the jacket is to reduce the temperature of the fermenter. Compared with the general jacket, the honeycomb jacket equipment greatly reduces the jacket wall thickness and the inner tube wall thickness, and the manufacturing cost is reduced. From the perspective of heat transfer, the gap of the honeycomb jacket is smaller than that of the ordinary jacket, the flow area is smaller, the flow velocity of the fluid in the cavity is significantly increased, and a large number of honeycombs act as spoilers in the jacket. The fluid constantly changes the flow direction and flow velocity when flowing through the honeycomb points, forming turbulent vortices to accelerate heat exchange and greatly increase the heat transfer effect.

Coil

Definition:

The coil consists of a set of parallel metal tubes that are bent into a circular or oval shape to form a coil. It has the characteristics of high heat exchange efficiency, simple structure, easy installation and maintenance.

Principle:

In beer equipment, coil jackets are often used to control fermentation temperature and cool beer. It achieves the effect of cooling and heat preservation by utilizing the heat exchange area of the coil jacket. In the coil jacket, the heat exchange fluid (such as cooling water or refrigerant) flows through the metal tubes to take heat away from the beer equipment or transfer heat to the beer equipment. Since the heat exchange area of the coil jacket is large, the temperature of the beer equipment can be controlled more effectively.

What is the difference between a jacket and a coil?

Jackets are generally used for fermentation tanks below 200HL. Due to uniform cooling, they can make up for the shortcomings of insufficient heat convection of the beer inside some small tanks.Coils are usually used for large tanks such as 500HL, 1000HL, 3000HL, and 6000HL. By realizing automatic welding by machines, labor costs and the instability of manual welding can be reduced. Since the heat convection inside large tanks is relatively intense, even if the coiling does not have a good turbulent effect, the tank will not freeze.

In summary, there are differences in heat exchange efficiency, structural form and application range between Miller plates or coils for fermentation tanks in beer equipment. It is necessary to select a suitable jacket method according to specific usage scenarios and requirements.

Edited by Cassie

E-mail:[email protected]

.jpg)

Get A Quote