Bunging valves, also know as spunding valve, pressure relief valves or fermentation valves, is popularly used in beer fermenting as a professional tool for pressure-regulating. Here are some introductions of its function and why it should be used in beer fermenting, if you are like some more explanations or assists for this item, feel free to drop us a message please, we’d be happy to help anyway we can!

1. What is a Bunging Valve?

A bunging valve is a pressure-regulating device installed on fermenters or unitanks to control gas release during fermentation. It allows CO2 to escape while maintaining a sealed environment and preventing over-pressurization.

2. Key Functions

Gas Venting: releases CO2 produced by yeast during active fermentation.

Pressure Control: maintains safe internal pressure(e.g., 1-2 psi for ales, higher for pressure-fermented lagers).

Oxygen Exclusion: prevents air/contaminants from entering the fermenter while allowing gas to exit.

Safety: acts as a failsafe to avoid tank rupture due to excessive pressure.

3. How Bunging Valves Work

Passive Mode: during primary fermentation, yeast generates CO2, which pushes through the valve. The valve’s weight or mechanism opens at a set pressure threshold (e.g., 5 psi), releasing gas.

Pressure Fermentation: for styles requiring carbonation during fermentation(e.g., spunded lagers), the valve holds back pressure to retain CO2 in the beer.

4. Do You Need a Bunging Valve?

Yes, in most cases-here’s why:

Safety: fermenters can overpressurize if CO2 isn’t vented, risking explosions(especially in sealed tanks).

Flavor Protection: prevents oxidation by keeping the system closed to external air.

Process Control: critical for pressure fermentation and carbonation management.

Exceptions:

Open fermentation: traditional Belgian ales in open vessels.

Small-scale homebrewing with airlocks(though less precise).

5. Types of Bunging Valves

Choose based on your fermentation style and scale:

Weighted Bunging Valves:

Simple, low-cost design using a weighted cap.

Adjust pressure by adding/removing weights.

Ideal for basic pressure control in smaller fermenters.

Spring-Loaded Pressure Relief Valves:

Precision control via adjustable spring tension.

Set exact pressure thresholds (e.g., 15 psi for spunding)

Common in commercial unitanks and bright tanks.

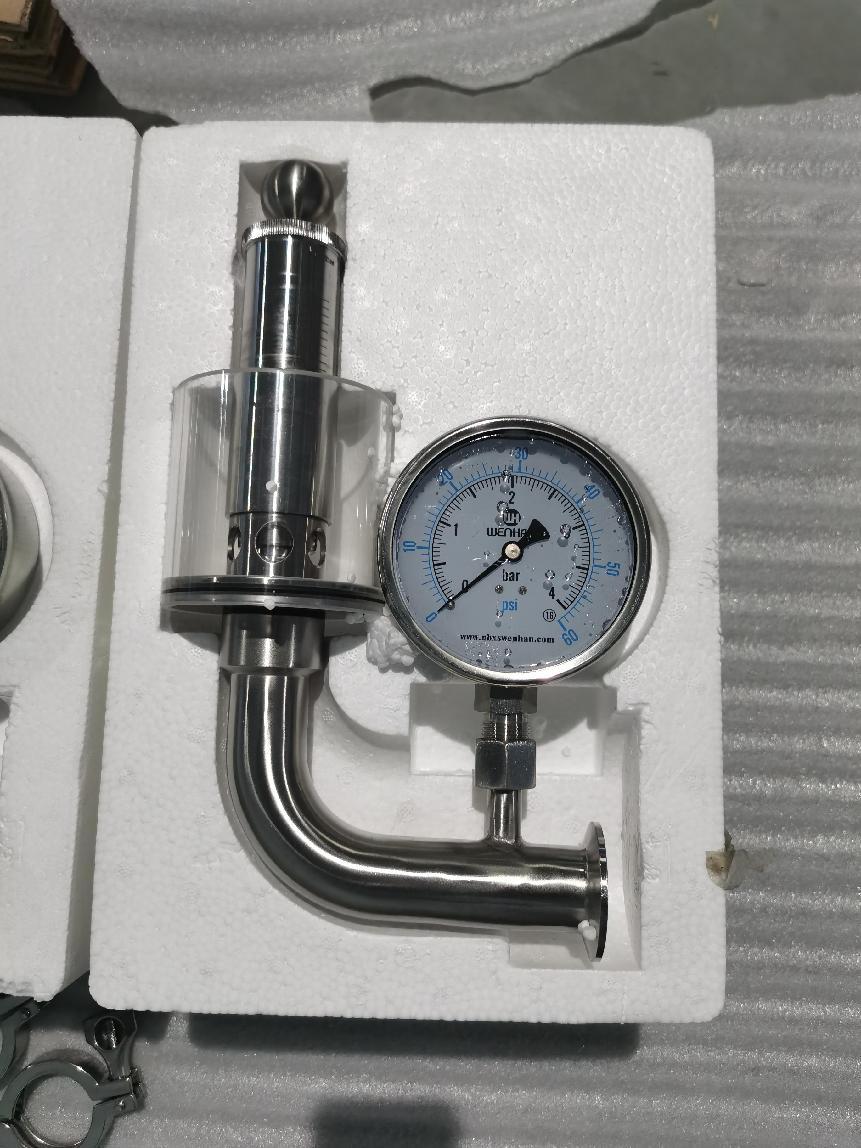

Tri-clamp Sanitary Valves

Hygienic, CIP-compatible design for large-scale brewing.

Often paried with pressure gauges for real-time monitoring.

6. Key Considerations When Choosing:

Pressure Range: match the valve’s range to your fermentation needs (e.g., 0-30 psi).

Material: stainless steel: corrosion-resistant, durable and CIP-safe.

Sanitation: ensure the valve is easy to disassemble and clean. (e.g., tri-clamp fittings).

Integration: compatible with your fermenter’s port size(e.g., 1.5” tri-clamp, NPT threaded)

7. Final Recommendation

Commercial Breweries: Invest in spring-loaded stainless steel valves. (e.g., 15-30 psi range) for precision and safety.

Craft/Nano Breweries: Weighted or adjustable valves are cost-effective for smaller tanks.

Pressure Fermentation Lovers: Pair a bunging valve with a spunding valve for end-stage carbonation control.

If you have any questions or hesitates for this, feel free to let us know your fermenter type, batch size or other brewing details, our team is here ready to help!

Cheers&Best Regards,

Sharon

E: [email protected]

.jpg)

Get A Quote