As a professional tool in beer brewing industry, carbonation stone is commonly used for craft and micro breweries to efficiently dissolves CO2 into beer. Whether its necessary or should be used depends on multiple factors including fermenter size, production scale and beer styles, etc. Here are some suggestions about if carb stone should be used in different brewing system, hope to help you with some references, if you have any hesitates about this please feel free to drop us a message, we’d be happy to help!

1. What is Carbonation in Beer Fermentation?

Definition

Carbonation refers to the process of dissolving carbon dioxide (CO2) into beer to create effervescence, mouthfeel, and aroma release. It’s a critical step for achieving the desired sensory profile of beer.

2. Functions of Carbonation

Flavor Enhancement: CO2 lifts volatile aromas, improving perceived freshness.

Mouthfeel: proper carbonation adds body and a crisp, refreshing texture.

Preservation: dissolved CO2 inhibits microbial growth, extending shelf life.

Style Compliance: different beer styles (e.g., lagers vs. stouts) require specific carbonation levels. (e.g., 2.0-2.8 volumes of CO2 )

3. Do You Need a Carb Stone for Fermenters?

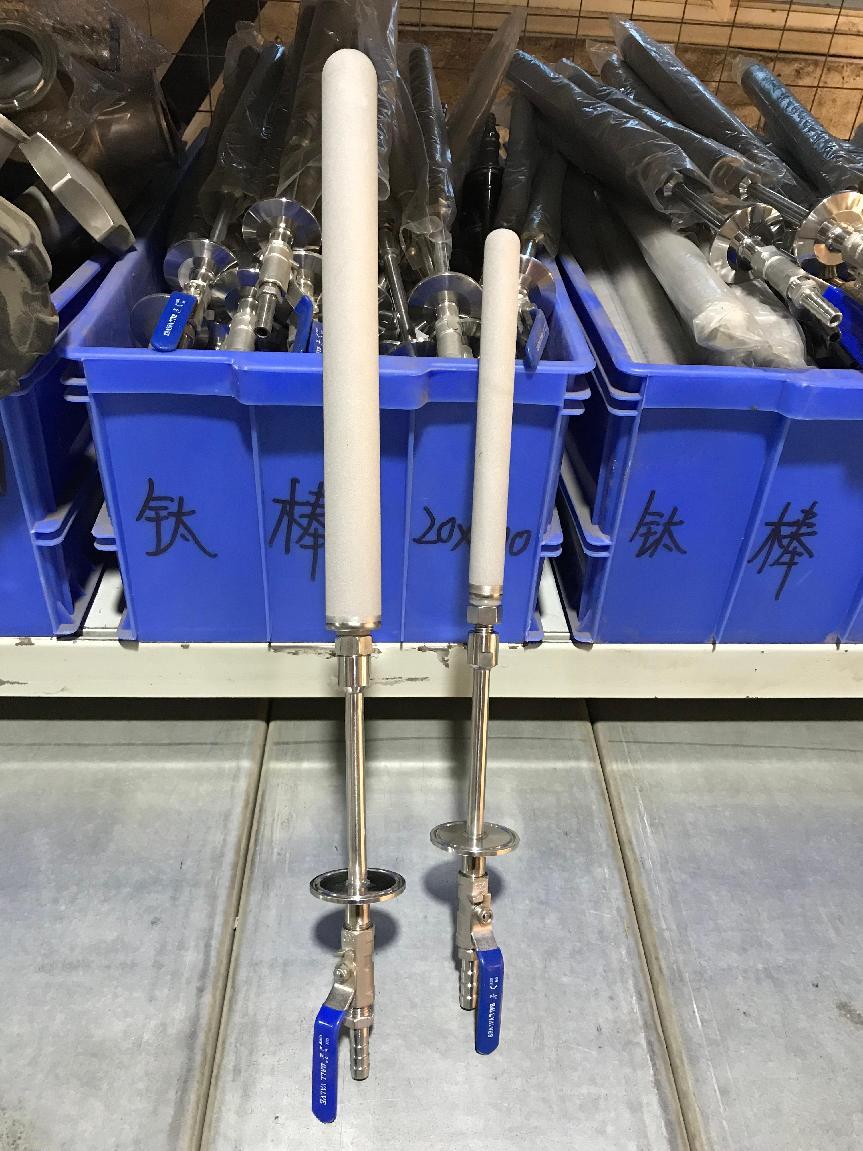

A carb stone is a porous device(typically stainless steel or ceramic) that efficiently dissolves CO2 into beer. Here is how to decide if its necessary for your setup:

When a carb stone is recommended:

Force Carbonation

If you’re using a unitank(fermentation+carbonation in one vessel) or a bright tank, a carb stone speeds up CO2 dissolution. It allows precise control over carbonation levels within hours, bypassing the slower natural carbonation process(e.g., bottle conditioning)

Consistency

Carb stones ensure uniform CO2 distribution, critical for large batches or commercial production.

Time Efficiency

Ideal for breweries with tight production schedules (e.g., carbonating a 1000L batch in 24-28 hours vs. Days).

4. When a Carb Stone Might Not Be Necessary:

Natural Carbonation:

If you rely on secondary fermentation(e.g., adding priming sugar to bottles/kegs), CO2 is naturally produced by yeast, and a carb stone isn’t needed.

Small-Scale Brewing:

For nano-breweries or homebrewers, manually agitating the beer while injecting CO2 may suffice, though less precise.

5. Practical Advice for Choosing a Crab Stone:

If you opt for a carb stone, consider these factors:

Material:

Stainless Steel(304/316L): Durable, easy to clean, and CIP(Cleaning in Place) compatible.

Ceramic: Higher porosity for finer bubbles but more fragile.

Pore Size:

0.5-2 microns: Smaller pores create finer bubbles, improving CO2 dissolution efficiency.

Integration with Fermenter:

Ensure the carb stone is installed at the bottom of the fermenter/bright tank for optimal gas dispersion.

Cost:

Carb stones range from $50-300+ depending on size and material, budget-friendly options exist for small tanks.

6. Final Recommendation:

For Commercial Breweries: a carb stone is highly recommended for efficiency, consistency and scalability. Pair it with a unitank or bright tank for best results.

For Small Batch/Craft Breweries: a carb stone is still beneficial but prioritize compatibility with your existing setup.

If you have any questions or other interested information about this, please feel free to drop us a message, our team is here ready for help!

Cheers&Best Regards,

Sharon

E: [email protected]

.jpg)

Get A Quote