As the craft beverage industry continues to grow, many microbreweries are exploring ways to diversify their offerings by venturing into distillation. Adding spirits like whiskey, gin, or vodka to your product lineup can not only boost revenue but also expand your brand’s reach. However, choosing the right distillation equipment for your microbrewery is a critical decision that requires careful consideration. Here we are happy to discuss some key factors to choose distillation equipment with you, hope they are make sense to you when you choosing distillation equipment.

1. Understand Your Goals

Before diving into the specifics of distillation equipment, take the time to clearly define your objectives. Consider:·What types of spirits do you plan to produce? Whiskey, gin, vodka, or brandy?

·What is your target production volume?

·Are you aiming for small-batch, artisanal products or higher-volume production?

·Do you want to use your existing brewing setup for part of the process (e.g., mash preparation)?

Your answers to these questions will significantly influence the type and size of distillation equipment you need.

2. Types of Distillation Equipment

There are two primary types of distillation equipment to consider:Pot Stills

Pot stills are ideal for producing spirits with rich flavors, such as whiskey, rum, and brandy. They are relatively simple in design and consist of a heated pot, a condenser, and a connecting swan neck. Pot stills are well-suited for small-batch production and can handle a variety of recipes.Advantages:

·Best for flavorful spirits like whiskey and rum.

·Allows greater control over flavor profiles.

·Suitable for smaller production volumes.

Considerations:

·Less efficient for high-volume production.

·Requires multiple distillations for high-proof spirits like vodka.

Column Stills

Column stills (also called continuous stills) are more complex and are designed for high-volume production and higher-proof spirits like vodka and gin. These stills have multiple plates or trays that allow for continuous distillation.Advantages:

·High efficiency and consistency.

·Can produce neutral spirits with higher alcohol content.

·Ideal for large-scale production.

Considerations:

·Higher initial investment.

·Less control over flavor complexity compared to pot stills.

3. Size and Capacity

The size and capacity of your distillation equipment depend on your production goals and available space. For a microbrewery:**Small-scale operations: A pot still with a capacity of 50L to 300L is sufficient for experimenting with recipes or producing small batches.

**Medium-scale operations: For slightly larger volumes, consider equipment in the 500L to 1000L range.

**Large-scale operations: If you’re planning to scale up significantly, a 2000L+ still or a combination of pot and column stills might be necessary.

It is also important to consider the frequency of distillation. A smaller still can work well if you plan to run it frequently, while larger equipment is better for fewer, higher-volume runs.

4. Materials and Build Quality

The material of the still directly affects the quality and flavor of the spirits produced. The most common materials are:**Copper: Preferred for its ability to remove sulfur compounds and enhance flavor. Copper stills are widely used for whiskey and other flavorful spirits.

**Stainless Steel: Durable, cost-effective, and easy to maintain. Stainless steel is often used for neutral spirits or as a base material combined with copper components.

High-quality construction ensures longevity and consistent performance. Look for equipment with precise welds, reliable seals, and robust fittings to avoid leaks or contamination.

5. Heat Source

The type of heat source is another crucial consideration. Common options include:***Steam: Steam jackets or coils provide even, controlled heating, making them ideal for larger setups. However, they require a separate boiler.

***Direct Fire: Economical and simple to set up, direct fire is suitable for small pot stills but can cause scorching if not carefully managed.

***Electric: Electric heating is clean, efficient, and well-suited for smaller stills, especially in confined spaces.

Choose a heat source that aligns with your production scale, budget, and facility setup.

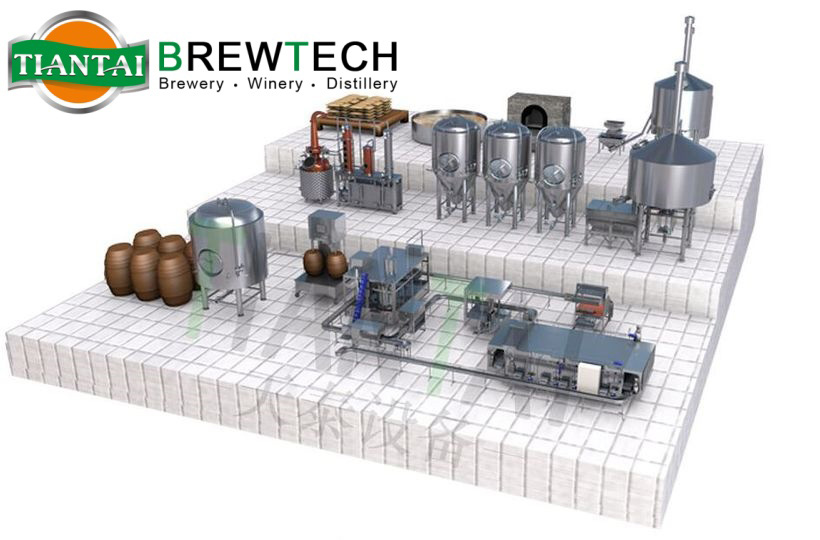

6. Integration with Existing Equipment

One advantage of expanding from brewing to distilling is the ability to repurpose some of your existing equipment. For example:**Mash Tuns: Your existing mash tun can be used to prepare wash for distillation.

**Fermenters: Glycol-cooled fermenters are excellent for maintaining precise fermentation temperatures for spirits.

When selecting distillation equipment, ensure it complements your current brewing setup to maximize efficiency and reduce upfront costs.

7. Compliance and Licensing

Distillation is heavily regulated, and compliance is critical. Before purchasing equipment, familiarize yourself with local laws regarding:·Licensing requirements for distillation.

·Production limits for micro-distilleries.

·Equipment certifications and safety standards.

Work closely with your equipment supplier to ensure the still meets all regulatory requirements in your region.

8. Supplier Selection and Support

Choosing a reputable supplier is just as important as selecting the right equipment. Look for a manufacturer that:·Offers customized solutions tailored to your needs.

·Provides installation, training, and ongoing technical support.

·Has a strong track record and positive customer reviews.

A reliable supplier can guide you through the selection process and help you avoid costly mistakes.

9. Budget Considerations

Distillation equipment is a significant investment, so it’s essential to balance quality and cost. Key factors that influence pricing include:·Size and capacity.

·Material (copper vs. stainless steel).

·Complexity (pot still vs. column still).

While it’s tempting to choose the cheapest option, investing in high-quality equipment pays off in the long run through better performance, durability, and product quality.

10. Future Expansion

Finally, think about your long-term plans. As your business grows, you may need to scale up production or diversify your product range. Consider modular equipment that can be upgraded or expanded to accommodate future needs. This approach minimizes disruption and ensures your investment remains viable as your distillery evolves.If you are plan to start your distillation business, Tiantai is here to support you every step of the way. Contact us today to discuss your equipment needs and take the first step toward expanding your product range!

Edited by Cassie

E-mail:[email protected]

.jpg)

Get A Quote