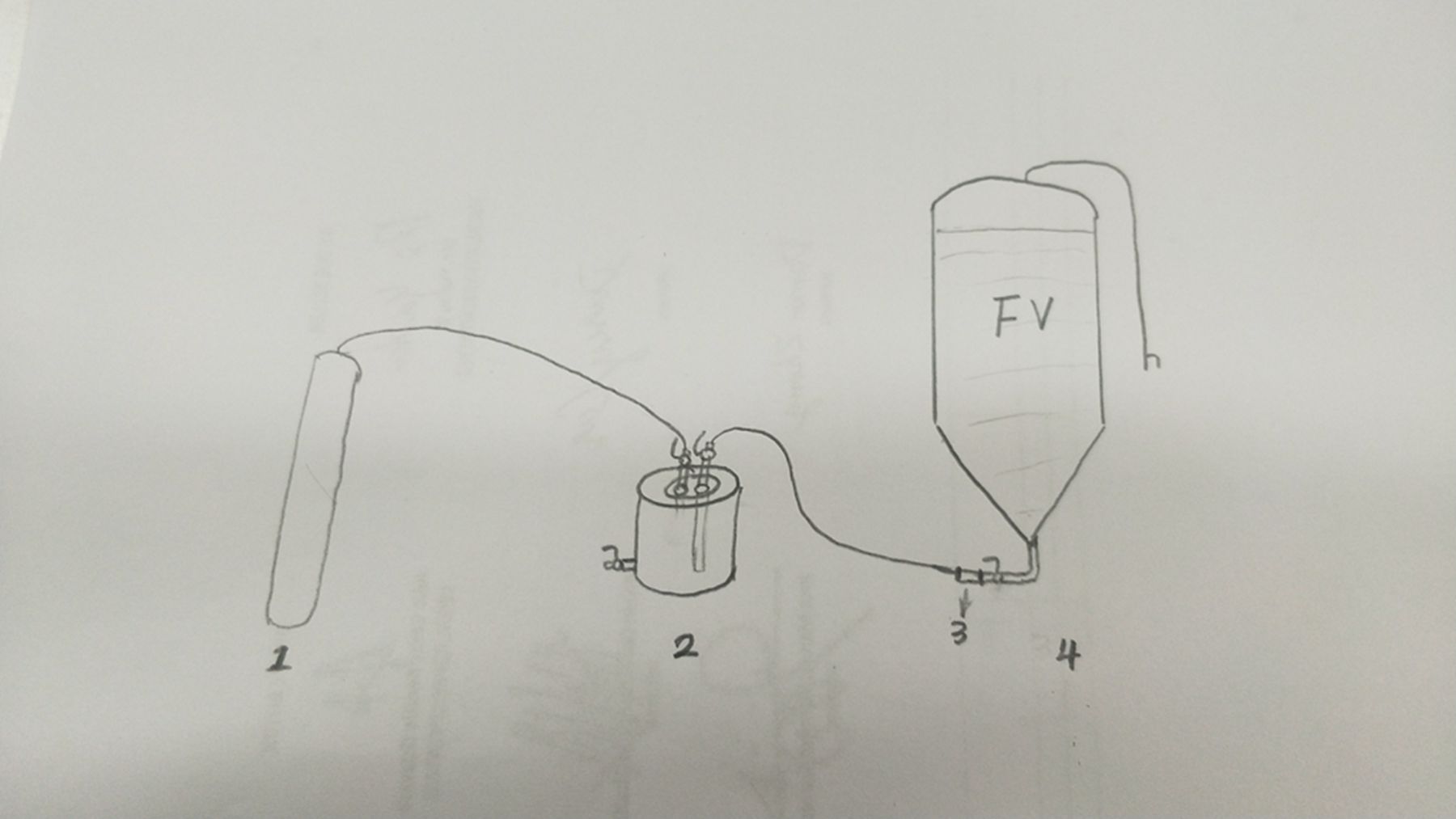

1 is sterile compressor air/oxygen/CO2 source;

2 is our yeast feeder;

3 is sight glass;

4 is fermetner with wort.

First step, sterilize all tubing, yeast tanks, sight glasses and interfaces;

Second step, pour the activated yeast into the yeast feeder or activate it directly in the yeast feeder;

Third step, open all valves that need to be operated in sequence;

Forth step, quickly open the air supply, and watch the sight glass at the same time.(It takes only a few seconds to complete the work of yeast addition.)

Fifth step, close the valve of fermenter and air supply at the same time;

Final step, check if all yeast has been added into FV, then clean yeast addition feeder.

For some brewer and brewmaster, it is not necessary. It depends on your personal habits.

Since the problem with any in-line pitching system is keeping all hoses, yeast addition tank or top pressure gas supply clean and completely sterile, which might well prove harder than simple manhandling of containers.

The yeast addition tank and the compressor air supply should not be expensive in your local.

Edited by Damon

E:[email protected]

.jpg)

Get A Quote