In the competitive world of brewing, maintaining high-quality standards while ensuring product safety is a top priority for every brewery. One critical piece of equipment that plays a significant role in achieving this is the sterilization retort. Often overlooked, this advanced sterilization system is essential for preserving the freshness, extending the shelf life, and maintaining the flavor integrity of various beer and beverage products.

.jpg)

What Is a Beer Sterilization Retort?

A sterilization retort is a high-pressure vessel used for thermal processing to eliminate harmful microorganisms in packaged beverages. It operates by using steam, hot water, or a combination of both to heat the product to a specific temperature for a set duration, ensuring complete sterilization. This method is commonly employed in breweries that produce canned or bottled beers, as it enhances microbial stability and extends product longevity without relying on excessive preservatives.Why Breweries Need Sterilization Retorts?

1. Ensuring Product SafetyBeer and other fermented beverages can be susceptible to microbial contamination, which may result in spoilage or off-flavors. A sterilization retort effectively eradicates bacteria, yeasts, and molds, ensuring the final product is safe for consumption and meets regulatory food safety standards.

2. Prolonging Shelf Life

For breweries aiming to distribute their products over long distances, maintaining shelf stability is crucial. Pasteurization through sterilization retorts significantly extends the shelf life of canned and bottled beverages, allowing breweries to reach wider markets without compromising product quality.

3. Maintaining Flavor and Quality

Unlike traditional pasteurization techniques, modern sterilization retorts provide precise control over temperature and processing time. This helps breweries maintain the original flavor profile and aroma of their beers, ensuring customers receive a consistently high-quality product.

4. Reducing Dependence on Preservatives

With the increasing demand for natural and preservative-free products, breweries must find alternative methods to maintain product integrity. Sterilization retorts allow brewers to reduce or eliminate preservatives while still ensuring microbiological stability, meeting consumer preferences for clean-label beverages.

Types of Sterilization Retorts Used in Breweries

Breweries utilize different types of sterilization retorts based on their production requirements and product packaging. The most common types include:1. Steam Retort

Steam retorts use saturated steam to rapidly heat the packaged product, providing uniform temperature distribution and efficient sterilization. This method is particularly effective for beer and beverages in metal cans.

2. Water Spray Retort

This system sprays heated water onto the product, ensuring even heat penetration and reducing thermal shock to the packaging. It is ideal for glass bottles and PET containers.

3. Water Immersion Retort

In this method, the packaged products are fully submerged in hot water, allowing for uniform heating and gentle processing. It is commonly used for premium craft beers that require precise temperature control.

4. Overpressure Retort

Overpressure retorts combine steam and air to apply external pressure on the packaging, preventing deformation of lightweight containers like plastic bottles and flexible pouches.

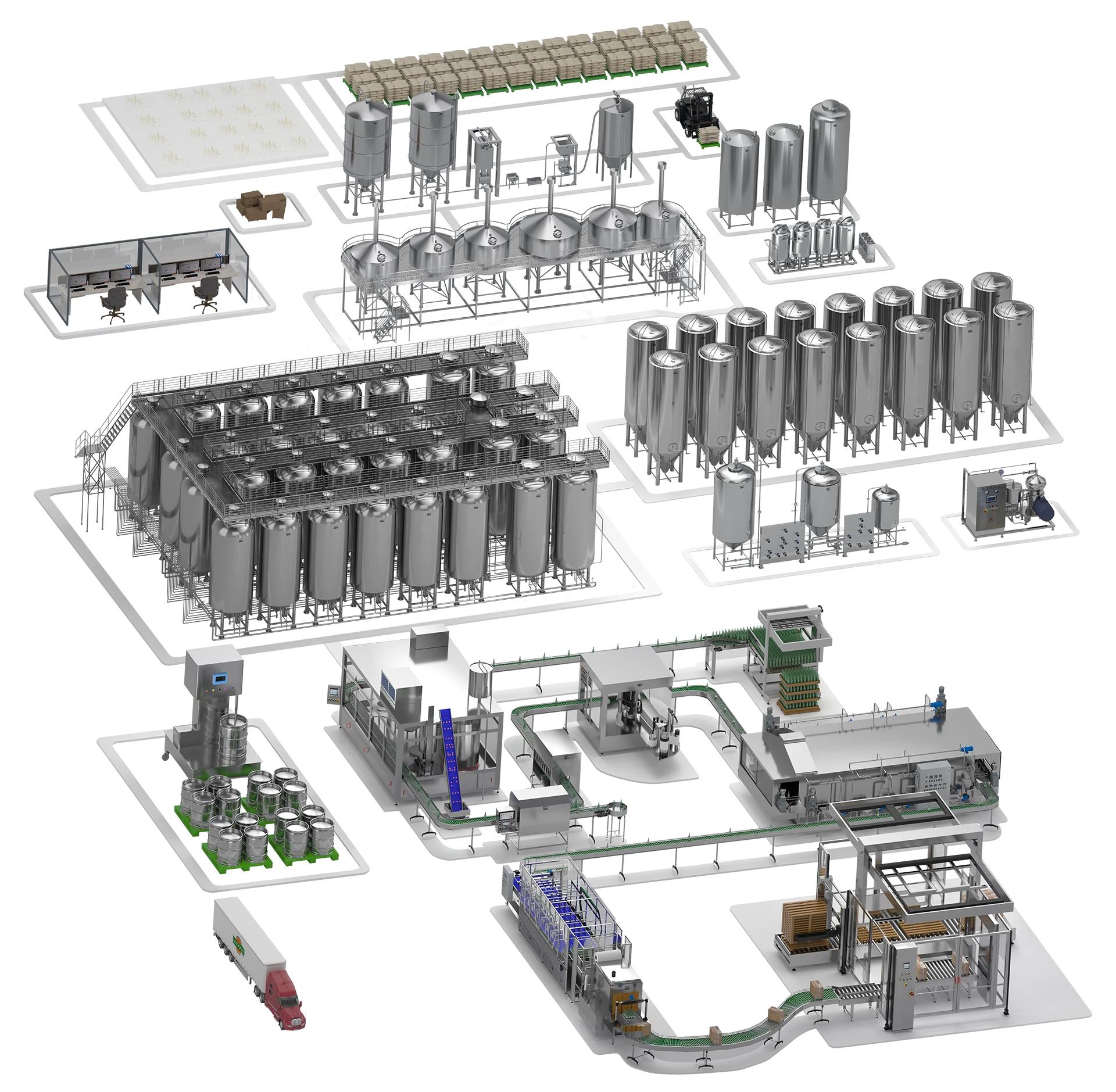

Integrating a Sterilization Retort into Brewery Operations

When integrating a sterilization retort into a brewery's production line, several factors must be considered:Production Volume: Choosing the right retort capacity ensures efficiency in sterilization cycles without bottlenecking production.

Packaging Material: Different materials require different sterilization methods; selecting the right retort type prevents packaging damage.

Automation Level: Modern sterilization retorts offer automated control systems for precise temperature and pressure regulation, reducing labor costs and increasing operational efficiency.

Energy Efficiency: Investing in energy-efficient retorts can significantly reduce operational costs while maintaining sustainability in brewing practices.

The Future of Sterilization Retorts in Brewing

As the brewing industry continues to innovate, the role of sterilization retorts is becoming increasingly significant. Advancements in smart automation, real-time monitoring, and energy-efficient sterilization processes are paving the way for more sustainable and high-quality brewing operations. With consumers demanding fresher and preservative-free beverages, breweries that invest in advanced sterilization technology will gain a competitive edge in the market.Sterilization retorts are an essential component in modern brewing, ensuring product safety, extending shelf life, and maintaining the integrity of beer and beverage flavors. By integrating a high-quality sterilization system, breweries can enhance their production efficiency, meet industry regulations, and cater to the evolving preferences of consumers worldwide. Investing in sterilization retorts is not just about compliance—it’s about delivering exceptional quality that keeps customers coming back for more.

Tiantai provides customizable brewery equipment to fit the unique needs of each brewery. If you are plan to expand your brewery business, Tiantai is here to support you every step of the way. Contact us today to discuss your equipment needs and take the first step toward expanding your product range!

Edited by Cassie

E-mail:[email protected]

.jpg)

Get A Quote