-- It is strictly forbidden to use detergents or disinfectants containing Cl for equipment cleaning.

-- If the equipment will not be used for a long time, please clean the equipment thoroughly before decommissioning, and close all valves after the water runs out. Before restarting the equipment after a long period of non-use, please clean the equipment thoroughly, and the cleaning can be repeated several times.

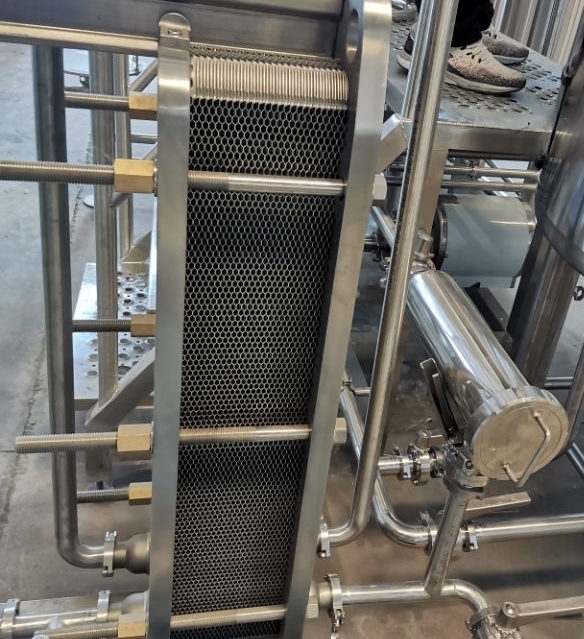

-- The plate heat exchanger should be disassembled and cleaned after long-term operation or long-term use. It is forbidden to use metal brushes during cleaning, and it is forbidden to bend, twist, step on, and squeeze the heat exchanger plates. To be replaced in time.

-- Regularly check the wiring and grounding of each motor and pump to ensure correct wiring.

Check the oil level of the geared motor and hydraulic device, and the stirring motor should be regularly added with lubricating oil according to the instructions.

Regularly check whether the connecting parts of stirring and tiller are tightened. The pumps used shall not be idling or reversed, and the seals of the pumps shall be replaced in time if the pumps are found to be leaking.

-- Always check whether there is foreign matter in the hopper of the pulverizer, check whether the fasteners on the pulverizer are loose, the tightness of the drive belt of the pulverizer and the reliability of each safety protection device. Clean the grinder rollers regularly.

-- Always check whether the pressure gauges and safety valves of the steam heating equipment are normal, and ensure that the steam traps are unblocked; if the liquid level is not reached, the heating must not be turned on! When the equipment is running, high-temperature pipelines such as steam and wort and the top of the mashing equipment should hang warning signs to prevent burns.

-- It is forbidden to extract wort with large flow during filtration, which will damage the sieve plate. When the equipment is not in use, no heavy objects should be placed on the sieve plate to avoid deformation of the sieve plate. Ensure that all mechanical parts run smoothly when the equipment is running.

-- Check the plate heat exchanger at any time for leaks, leaks, and liquid leakage. If there is, repair it immediately.

-- Pay attention to the concentration of alkaline water in the alkaline water tank at any time. If it is found that the concentration of alkaline water is too low or too turbid, it cannot be used for washing and should be replaced in time.

-- Check each pipeline valve at any time, if any leakage is found, it should be repaired or replaced in time.

-- Always check the indications of the meters on the switchboard. For the temperature calibration of the digital temperature control meter, a mercury (or alcohol) thermometer can be used to calibrate the temperature to ensure the accuracy of the process parameters.

-- The mashing equipment should be rinsed with water in time after each use, and the mashing pipeline, plate heat exchanger and wort pipeline should also be rinsed clean.

-- It is strictly forbidden to grab and climb the equipment process pipeline, cooling pipeline and exhaust pipe.

-- When the equipment is shut down for maintenance, the power should be cut off and a warning sign should be hung.

If you are looking for brewery system, feel free to contact us! We supply 2-150HL complete beer brewing equipment including malt milling equipment, brew houses equipment, beer fermenters /fermentation tank, brite beer tanks, beer bottling machine,beer canning machine, beer kegging machine, hopping machine etc. Everything in brewery are all in our list.

Edited by Cassie

E-mail:[email protected]

.jpg)

Get A Quote