Here is Sharon from Tiantai Beer Equipment Co., Ltd.

Welcome to visit our brewery equipment website!

Here we’d like to introduce the equipment and configurations that usually recommended and included in the standard distillery system, if you are looking for similar type or size of equipment for your business, feel free to contact us for more interested information and details please, Cheers!

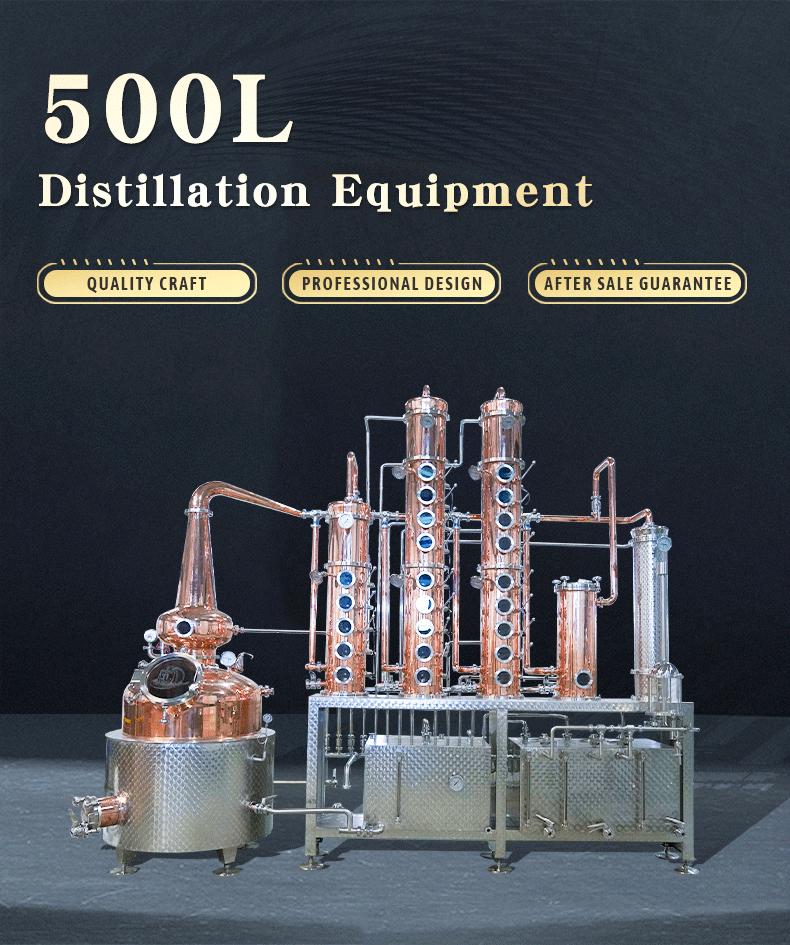

Part 1: Distiller Unit

As the main body for distillery system, there are all kinds and sizes of distillers configured for making all different types and degrees of spirits like gin, rum, vodka, brandy and whiskey, etc. Like the machine showed in above photo, this is a set of 500l distiller with customized 20 trays of columns(4 trays+8 trays+8 trays) for making both high and low degrees of alcohols, as you know that the higher the degree, the more columns needed. As for the heating method, normally there are both steam and electric heating sources supplied for options.

Besides, there are all the other special configurations are available to be custom-made as per personal requirements. For example, for the dephlegmators and condenser or even vapor pipelines, there are both stainless steel and red copper materials supplied for different budget conditions.

Part 2: Brewhouse/Cooker Unit

The second part included in the system would be the brewhouse unit(mash/lauter tun+hot water tank) to do the pre-mashing for distilling. Usually a double size of hot water tank is suggested to make sure enough and timely supply of distilling waters.

Part 3: Cooling Unit

Glycol cooling machines for cooling mashing liquid and fermenters, mainly including glycol water tanks, cold water tank, chillers and glycol pipelines, etc.

Part 4: Fermentation Unit

The number of fermenters are normally configured based on the kinds of spirits that intended to be distilled.

Part 5: CIP Unit

Cip cart provided for distilleries cleaning.

Your journey to brewing&distilling excellence is our top priority. We offer comprehensive customer support, from seamless installation to thorough staff training and ongoing maintenance services. Our team of experts stands by your side to ensure you're always one step ahead in the brewing world.

Other configurations and more details to be discussed to meet your personal demands and special requests, we shall be honored to support you build your brewery dream in any way we can.

Sharon

Email: [email protected]

.jpg)

Get A Quote