What are the Components/Vessels in a Craft Brewhouse?

The Hot Liquor Tanks

The hot liquor tanks(HLT), also referred to as a hot liquor tun, is a tank/vessel that heats the strike and sparge water to a desired temperature. The HLT is essentially a hot water heater, and the size of the HLT should be proportional to the size of your brew. For example, you would ideally use a 10 gallon HLT for a 5 gallon batch or 15 gallon HLT for a 10 gallon batch. Large-scale operations use an industrial-sized HLT to heat large amounts of water.

Hot Liquor Tanks are typically stainless steel and, depending on size, can range anywhere from 10 to 1000 gallons. Some breweries may use a Hot Liquor Tank / Mash Lauter Tank combination vessel, while others may invest in two designated vessels to expedite the process.

Mash Tuns/Lauter Tuns

The Mash Tuns/Lauter Tuns is a vessel used to mash the grist and hot water to create the wort (unfermented beer). The mash tun is a vessel in which mashing takes place and where wort (unfermented beer) is separated from the grains. Most homebrewers use a 10 or 15 gallon mash lauter tun to heat their sparge water.

Depending on the scale of production, brewpubs and breweries may use a mash lauter tun that holds 100 gallons or more. The majority of mash and lauter tun vessels are stainless steel.

Brew Kettles and Whirlpools

Brew Kettles, also known as boilers, boil kettles, or coppers (if made of copper), are vessels where the mash is boiled to a specific gravity, and hops and other flavorings are added. The boiling process allows for various chemical reactions to take place, including sterilization of the wort, releasing hop flavors, concentration of the wort, releasing bitterness and aroma compounds through isomerization, as well as stopping the enzymatic processes.

For smaller operations, homebrewers will frequently improvise by boiling the mash in the mashing vessel. However, more sophisticated brewpubs and breweries designate brew kettles for the boiling process, in addition to whirlpools, which allow the wort to settle. Whatever your preference, cleanliness and sanitation are essential for brew kettles.

Brew kettles are typically manufactured using stainless steel or copper (depending on the make and manufacturer) because these materials are easier to clean. Prices for brew kettles is determined by their size, manufacturer (US-made versus German or Chinese), and quantity. Some brew kettles are sold as sets, providing multiple boilers for simultaneous brews. Brew kettles are sized anywhere from 50L to 1000L (or greater), and are typically measured by the BBL production capacity, ranging from 1-7 BBL to more than 50 BBL.

Depending on your projected production capacity, as well as the heating process you plan on using (electric versus steam, direct versus indirect fire), you should speak with your supplier to determine what type and size of brew kettle would work best for your craft brewhouse.

Whirlpools allow the boiled wort, all soluble proteins (trub), and vegetable matter from the hops to settle and collect in the center of the kettle. By collecting in the center of the whirlpool, it is easier to remove the undesirable trub from the wort. The clear wort is then pumped through the heat exchanger and into the fermenter. Many brew kettles are designed to function as a whirlpool after the boiling process has occurred, and the wort may settle in the same vessel.

Heat Exchangers

Heat exchangers, also referred to as wort chillers, allow you to cool your wort from boiling to yeast-pitching temperature in a timely manner. Immersion chillers, plate and counterflow wort chillers will exchange (or reduce) the heat to help improve overall beer clarity, and reduce the chances of off-flavors and contamination. In order to pitch the yeast and begin the fermentation process, the wort must first be cooled to a suitable temperature for fermentation.

Modern breweries typically utilize a plate heat exchanger, which contains ridged plates that form two separate paths. One path is for the wort, while the other path is for the cooling medium, which is typically water. Plate heat exchangers are usually made of stainless steel and brazed with copper. Depending on the brew capacity, you will need an appropriately sized plate heat exchanger to properly cool your wort when transferring it to the fermenter.

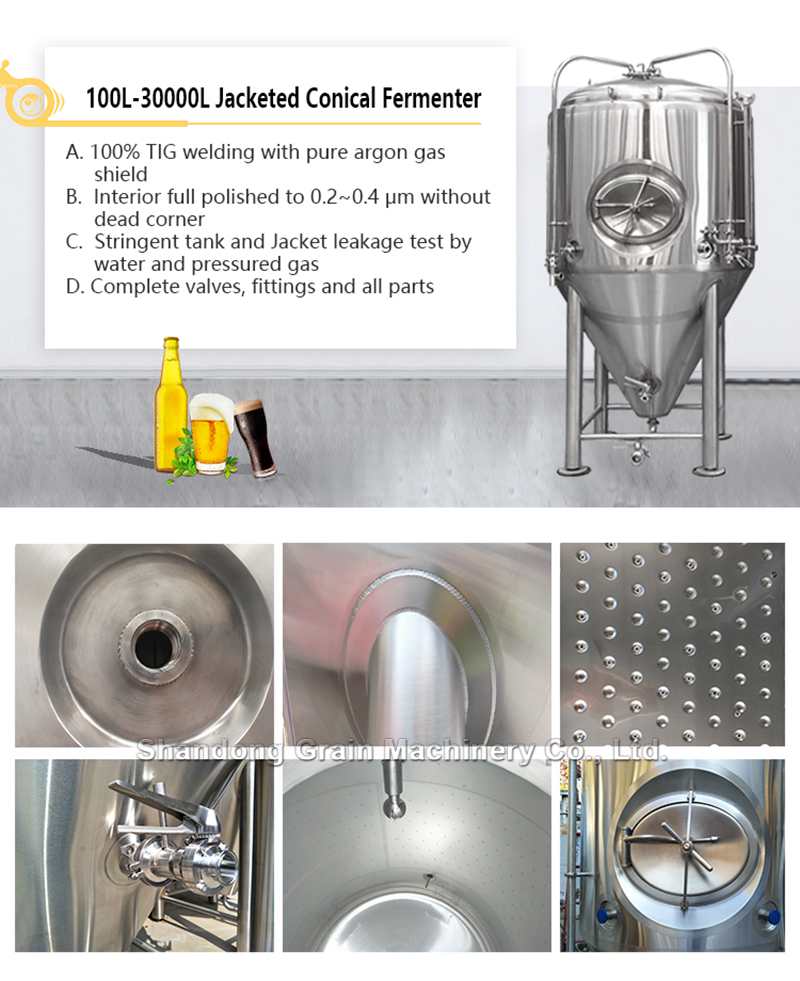

Fermentation / Aging Vessels

Fermentation tanks, also referred to as fermenters, are aging vessels where yeast is pitched into the wort, effectively turning it into beer. The wort is pumped into this vessel through a heat exchanger and then added to the previously pitched yeast, where it can begin fermenting. Some breweries have designated aging vessels where the beer is transferred for the aging process.

The number of required fermentation tanks is based on your brewing production. In general, the more fermentation tanks available, the more beer that can be simultaneously brewed, fermented, and aged. Similar to other vessels, fermentation tanks are usually stainless steel and range in size from 5BBL to 6,000 BBL. Depending on your floor layout and production output, tanks may be open or closed, horizontal with manholes, or vertical with conical bottoms. Unitank fermenters may be used for both fermenting and lagering. Today, most craft breweries use cylindroconical fermentation tanks, which are engineered with a conical bottom and a cylindrical top.

Get A Quote