The process of wort filtration is the longest among the four steps of mashing. We all want good quality wort and efficient extraction of sugars from the malt within a reasonable time frame. The load-bearing capacity of the lauter tun, the uniform distribution of the mash, the design of the rake bed, the wort collection system, etc. will all affect the filtration efficiency and effect. Today I am very happy to discuss with you the design of Tiantai lauter tun.

Tiantai lauter tun is made of food grade 304 stainless steel with insulation layer. A large-size side outlet door is installed on the front, and a sanitary EPDM rubber ring is used to strengthen the airtightness of the tank. With a glass sight glass, you can observe the state of the bad layer in the tank.

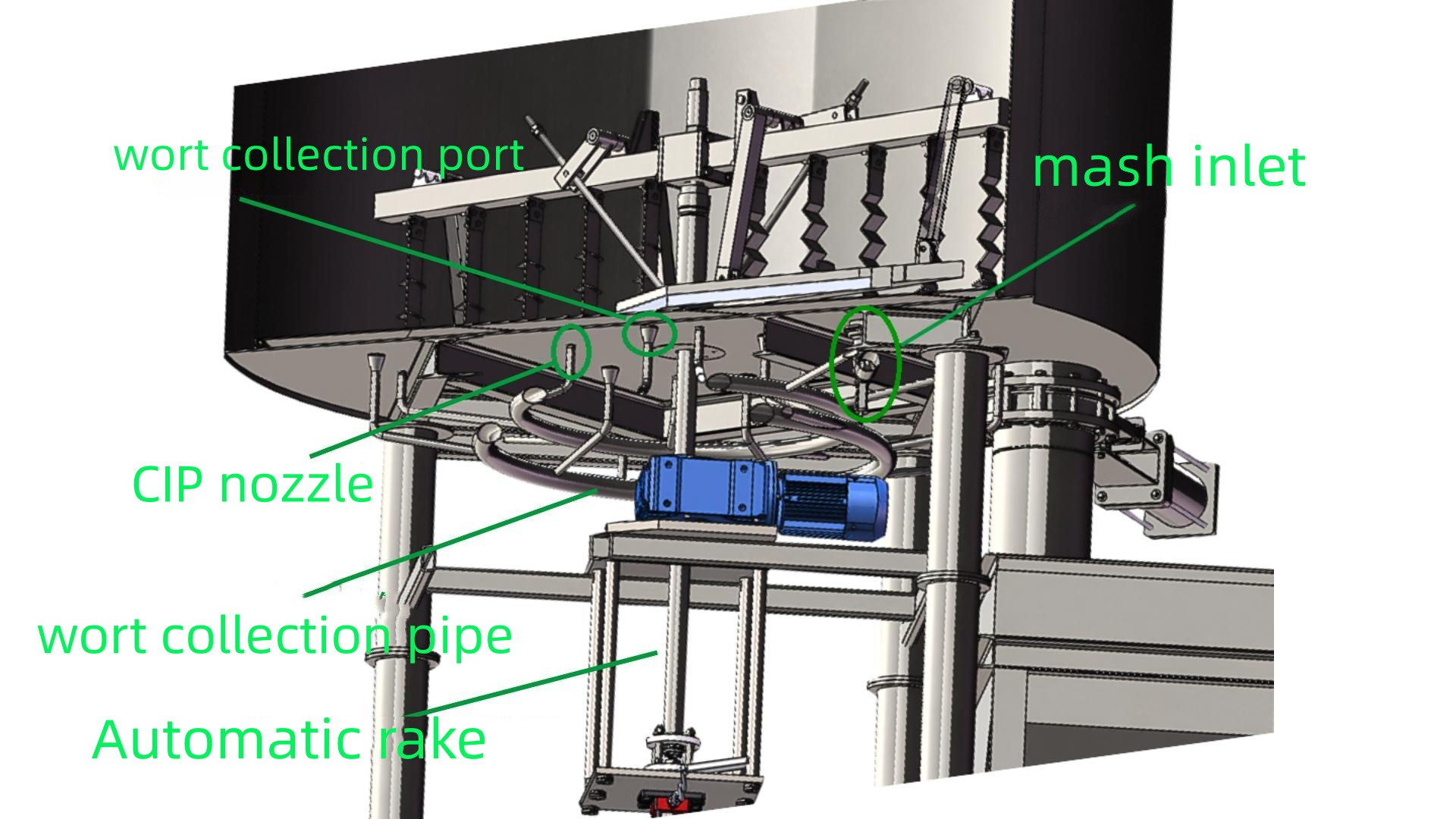

The mash inlet is at the bottom of the lauter tank, passing through the false bottom and the sieve plate, and the mash will be pumped from the mash tank into the lauter tank. There are 2~6 adjustable mash inlet valves installed at the bottom of the lauter tank, and the mash pumping process can be completed within 10 minutes.

The wort outlet pipes evenly distributed at the bottom of the tank and the wort collection circle in the center are cone-shaped. This design can ensure that the wort flows out smoothly and slowly, avoiding the phenomenon of slugging, and reducing the oxygen in the tank being sucked into the filtered wort.

Also visible at the bottom are the evenly spaced cleaning nozzles. After filtration, the bottom of the sieve plate can be rinsed and thoroughly cleaned with high-pressure water.

According to the volume of the filter tank and customer needs, we will also install a bottom outlet at the bottom. It is connected with the standard rake and controlled by the pneumatic valve to realize automatic spent grain discharge.

Inside the lauter tun, a CIP cleaning ball and a washing ring are installed on the top. The washing ring is made of food-grade stainless steel pipe at one time without welding. There are holes drilled at multiple angles on the pipe, and the sprayed water can cover the wheat grains layer more comprehensively, achieving a finer grain washing effect.

Further down, you can see the core design of the entire filter tank - the rake. After the first wort has been filtered, the spent grains are tightly squeezed together. At this time, the resistance of the grains increases and the flow of wort decreases, so it is necessary to loosen the grains with the aid of a cultivator. During the grain washing process, by adjusting the height of the rake, when rotating at different heights, the grain layer is loosened and a new wort channel is added to make the grain washing more thorough.

The false bottom and spent grains form the filter medium in the lauter. The inclined milling false bottom used in Tiantai filter tank has a porosity of 13%. The design of this false bottom can reduce the phenomenon that the grains of wheat grains fall into the gap and block the flase bottom, so that the filtration speed and effect are significantly improved.

Hope above discussion could let you know more about Tiantai brewery equipment.

If you are planning to build your own brewery. TIANTAI could help you answer your questions and supply brewery equipment. We supply 2-150HL complete beer brewing equipment including malt milling equipment, brew houses equipment, beer fermenters /fermentation tank, brite beer tanks, beer bottling machine,beer canning machine, beer kegging machine, hopping machine, yeast propagation equipment. We also supply all auxiliary brewery systems like steam heating pipe and valves, water treatment, filter, air compressor etc. Everything in brewery are all in our list.

Edited by Cassie

E-mail:[email protected]

.jpg)

Get A Quote