Hello there, welcome to visit our brewery equipment website!

This is Sharon here from Tiantai Brewery Equipment Company.

Here we’d love to introduce you this set of 500l two vessel brewhouse brewery equipment that newly finished earlier days, main configurations including the two-vessel brewhouse, fermentation tanks, glycol cooling system, 100L cip cart and other auxiliary equipment like bottle filling machine and keg washing machine, etc. If you are locating some similar size of equipment for your business, feel free to get back to to us at your conveniences for any more interested information please,

Cheers!

Designed for small size craft breweries, the 500l brewing system are being widely selected among customers,

With iconic structure of 2-vessel brewhouse, there are two batches of beer brewing are available to be operated at most per day with about 12 working hours.

Steam, electric and gas fire heating source are available to be customized based on your preferences.

Main configurations included in the standard system for your references:

1) Malt Milling Unit: Malt Mill[300-500kg/hr]

2) 500L Brewhouse:

500L Mash/Lauter Tun

500L Kettle/Whirlpool Tun

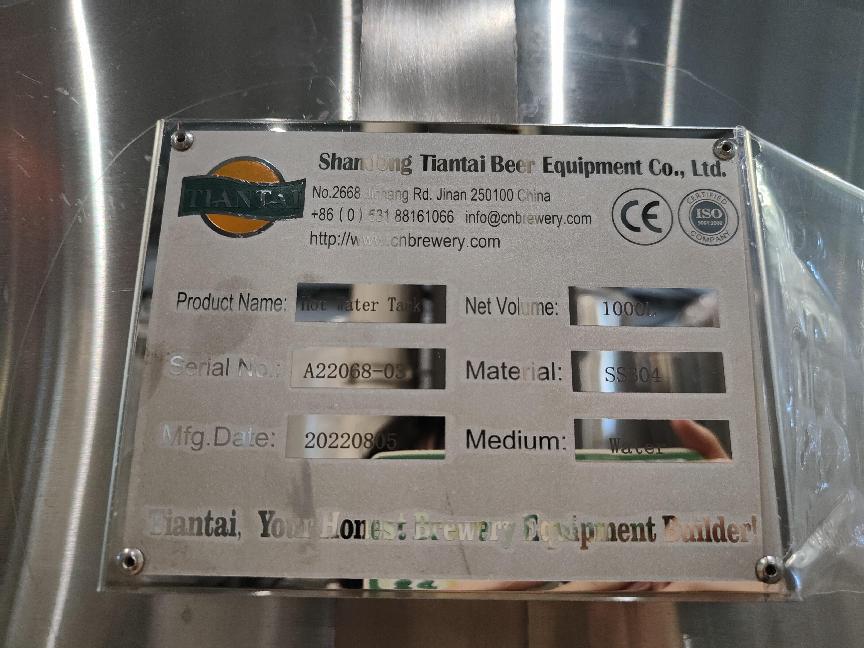

1000L Hot Liquor Tank

3) Fermentation Unit

500L&1000L Fermenters

4) Glycol Cooling Unit

1000L Glycol Water Tank

3HP Glycol Water Chiller

Glycol Pipeline

5) CIP Unit

100L Portable CIP Cart [Two Vessel]

6) Control Cabinet Unit

Brewery Instrumental Control Cabinet

The control cabinet is separated with fermentation system and mounted on brewhouse platform,

Floor-standing type are available to be provided for both brewhouse and fermentation system combined together.

Manifold customized for distributing liquids for mashing, sparging and cleaning, etc. as per special requests.

1000L fermenter with CO2 arm, rotating racking arm, spunding valve, carb stone and CIP arm equipped,

All tanks are customized with adjustable feet for leveling on uneven floors or fine height adjustments.

The side manway is designed to be robust and durable, ensuring a tight seal to maintain the integrity of the fermentation environment,

Its ergonomic placement allows for efficient operation and ensures that users can perform necessary tasks without strain.

Standard labels provided, it is also available to be customized based on your brewery logo if you prefer.

Customization services provided to meet all your special requirements, just feel free to let us know if there are any other requirements please.

Whether you are transitioning from a startup phase to an established business, or from basic equipment to more sophisticated configurations, our team would always be here ready to assist you with each step of the way!

If there are any new challenges or opportunities we might be able to serve you for your business or project, please don't hesitate to reach back at your conveniences for more interested information, we'd always be here ready to help!

Happy brewing and wish the best of luck for your business!

Sharon

E: [email protected]

.jpg)

Get A Quote