To establish a nano size craft beer plant from beginning, the 300l brewery system can be a perfect starting point. A 300l brewing system strikes an ideal balance between cost-effectiveness and production capacity, it is sufficiently to produce a respectable volume of beer, allowing for reasonable turnover without the need for an industrial-scale operation. This size is particularly advantageous for small to medium-sized breweries that aim to serve local markets, taprooms, and a limited number of pubs or restaurants.

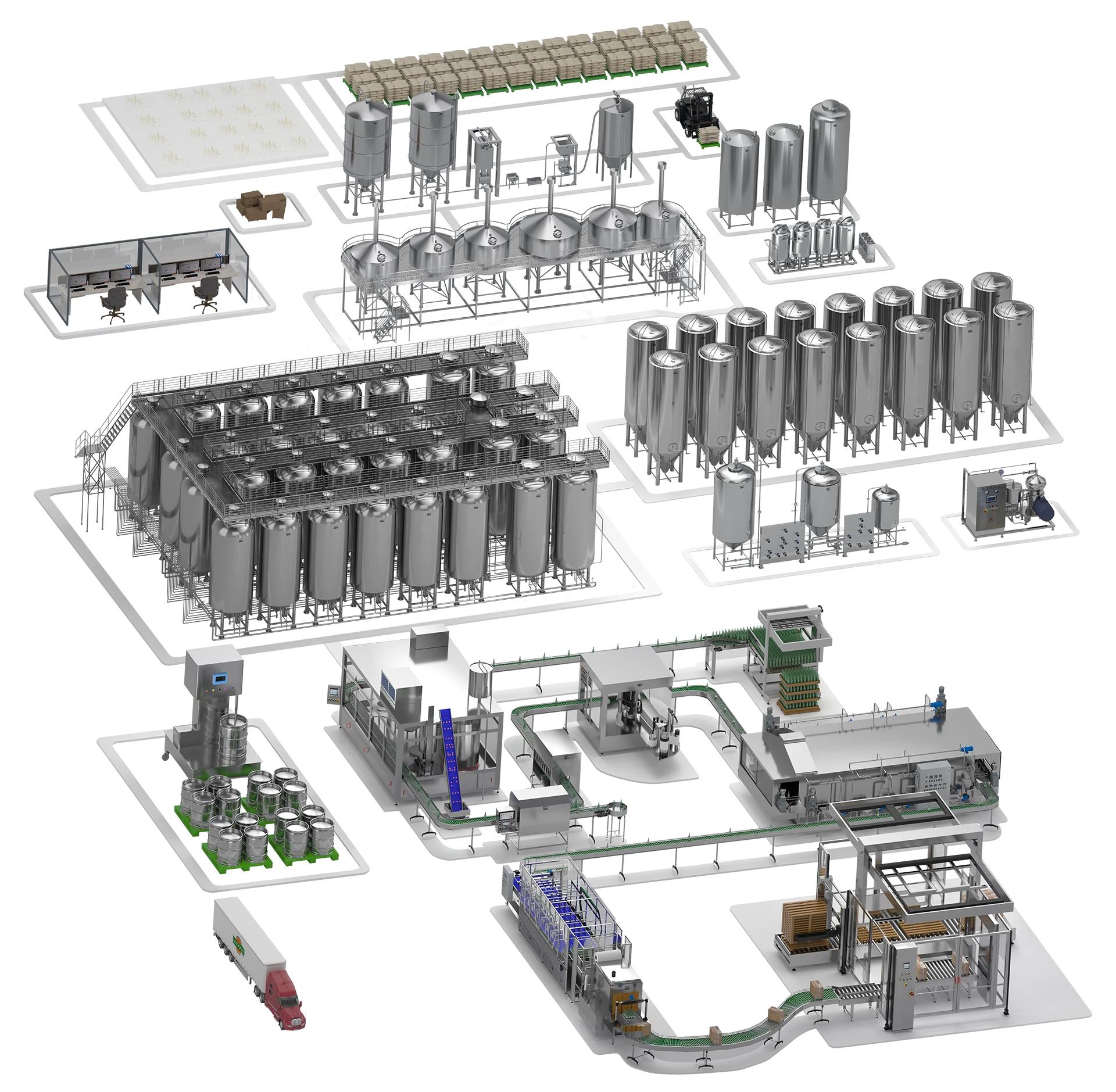

Key Components Included in the 300L Brewery System:

| Malt Milling |

100-150kg/Hr Malt Milling Machine [2-Roll as Standard, 4-Roll for Options] |

| Brewhouse |

2 Vessel Brewhouse System [300L Mash/Lauter Tun, 300L Kettle/Whirlpool Tun, 600L Hot Liquor Tank] |

| Fermentation Tank | Carbonation Stone, Bunging Valve, Level Indicator, Defoaming Tail, Dry Hopping Tank |

| CIP Cleaning |

Portable CIP Pump 100L Portable CIP Cart |

| Glycol Cooling |

600L Glycol Cooling Tank Glycol Chillers Transfers |

| Auxiliary Machine | Bottling Machine, Keg Machine, Canning Machine |

The 2 vessel brewhouse configuration is common for new breweries and those using recipes with single infusion mashes.

The configurations consists of Mash/Lauter Tun to perform both the mashing and lautering processes, and a kettle/whirlpool tun to boil the wort and whirlpool the wort to separate the trub. A 2-vessel configuration is ideal for the brewer’s ease of use with all process valves and pump controls positioned in optimal locations.

We offer a custom design variation that features the addition of a mash mixer inside the kettle to create a mash/kettle whirlpool. This scenario, the brewer would perform mashing, wort boil and whirlpool in the same vessel, while the lauter tun would be a single purpose vessel. The addition of the mash mixer gives the brewer the ability to use recipes with multiple step infusion mash rests.

Different Layout Designed&Customized Configurations:

The complete brewhouse is available to be customized on portable skid with caster wheels and handle for easy moving, there is also adjustable foot pad to fix the machine for stable operations.

Other Features of our System:

* Designing: brewery layout available to be designed at beginning for free to help checking the floor plan schedules or confirming the total areas required.

* Customization: customized configurations based on personal requirements. Logos available to be customized based on provided designs.

* Manufacturing: whole production conducted based on strict quality control and crafts management.

* Testing: complete testing and pre-running processed before final finishing.

* Delivery: delivering cargoes to sea port or to door services available to be provided.

* Installation&Maintenance: engineers available to be dispatched on the site to help with installing and training based on requirements.

* After-sales Service: after sales service provided for life.

Heating Source:

The heating source is available to be customized based on personal preferences, there are steam, electricity and gas fire available to be provided for options.

Advantages of 300L Brewing System:

1. Flexibility: this size allows for free experimentation with different recipes and styles without committing to large batches, which is nice option for breweries with no much experiences especially to start brewing business from the very beginning;

2. Cost-Effective: lower initial investment compared to larger systems, making it more accessible for small business owners.

3. Local Market Focus: ideal for targeting local consumers and building a brand within a specific community or region.

4. Scalability: it offers the opportunity to scale up production as the brewery grows in popularity.

5. Small Occupation: with compact layout design, the whole system occupies a rather small area to lower budget costs.

Turnkey solutions available to be provided from designing to manufacturing, delivering, installation, training and maintenance.

Please feel free to send us an email or give us a call for a quote or more interested information, Cheers!

Sharon

E: [email protected]

Tiantai Brewery Equipment Company

.jpg)

Get A Quote