Controlling Brewery Fermentation Temperature

Managing the temperature level of proactively fermenting wort can have a significant effect on the flavor of the finished beer. Fermenting over the regular temperature level array may produce too much fruity-flavored esters or harsh-flavored fusel alcohols. I as soon as made a set of ale throughout the summer season and enabled the fermentation temperature level to go beyond 80 掳 F (27 掳 C). The finished beer tasted like a batch of Juicy Fruit gum!

.jpg)

Many homebrewers do not have an innovative methods to preserve fermentation temperature levels in a suitable variety. This is the factor that historically several beers that needed to be fermented in a great environment (particularly ales) were made during the winter months and saved in caverns or cellars. This is also why I ferment ale in the winter and mead in the summertime, when my basement is in the proper temperature array for each and every type of fermentation.

Normal ale fermentation temperature levels vary from 68 to 72 掳 F (20 to 22 掳 C) as well as ale fermentation temperatures from 45 to 55 掳 F (7 to 13 掳 C). Maintain in mind that the warm produced by an energetic fermentation can heat a normal 5-gallon (19-L) set of beer by 10 to 15 levels Fahrenheit (5.5 to 8.3 degrees Celsius). Despite the fact that a cellar in a northern environment may be great enough to maintain ale fermentation from overheating, it is typically not cool sufficient to appropriately perform brew fermentation. On the various other hand, fermenting listed below the typical temperature level variety for an offered yeast strain may result in a slow or incomplete fermentation. What if your brewing area does not hold a preferable fermentation temperature throughout the time you desire to brew? Adhering to are a variety of strategies to aid manage fermentation temperature levels that vary from the easy to the innovative.

Keeping it trendy

A simple method to help cool your fermenting wort is by using evaporation, the same way our bodies cool themselves on a warm day. Instead of enabling the wort itself to evaporate, position the fermenter in a big bathtub or pan of water and cover it with a t-shirt or various other product that can wick the water out of the pan as well as allow it vaporize from the outer surface area of the fermenter, cooling it in the process. This approach functions best when the air surrounding the wet tee shirt is completely dry and/or distributed by a follower, allowing for enhanced dissipation of the water. Evaporative air conditioning using this strategy can maintain a fermenter around 5 to 15 degrees Fahrenheit (5.5 to 8.3 degrees Celsius) cooler than the surrounding air.

A somewhat much more aggressive technique to keeping your fermentation cool is to add ice to the water surrounding the fermentation vessel. This technique needs a little bit more keeping an eye on to be sure ice is restored as it thaws throughout active fermentation. This approach likewise makes it challenging to regulate the temperature level of the fermenting wort in an ice water bath, resulting in a situation where the wort may be maintained cooler than preferred. A little testing might be essential to determine if evaporative air conditioning and/or ice water cooling provides the correct temperature level array for your brewing atmosphere. A self glue temperature strip placed on the beyond a fermenting vessel above the level of an ice water bathroom can supply a simple as well as practical means of checking wort temperature during fermentation.

If the damp tee shirt and/or ice bath strategies prove insufficient to maintain your fermentation in the appropriate temperature level array, or will not give you sufficient control, there are more advanced techniques you can employ to do the job. By establishing a recirculating pump in a different container holding ice water (a shielded cooler jobs well) as well as pumping the chilled water to a bathroom surrounding your fermenter, you can accomplish much more control than with a straightforward ice water bath bordering the fermenter. By adjusting the rate of circulation or size of the water bath bordering the fermenter you may be able to maintain points cool without exaggerating it.

To give also much more control to a recirculating cool water system, you can include a temperature level controller with a temperature sensing probe. The temperature controller can be utilized to regulate the recirculating pump so it will pump cool water around the fermenter whenever the temperature of the fermenting wort rises over the preferred temperature level. Stopper thermowells are available to house a temperature noticing probe so it can be submersed in a carboy or fermenting container.

The very same temperature level controller can additionally be made use of to just control the temperature level inside a fridge or freezer. The thermostat can then be set to maintain the refrigerator or freezer in a temperature array for the design of beer being fermented or the stage of conditioning (lagering) preferred.

Temperature controllers can be found in both analog as well as electronic designs as well as have in between a 1 and also 4 level Fahrenheit (0.5 to 2.2 degree Celsius) differential respectively, hence maintaining the system they control in a 2 to 8 degree Fahrenheit (1.1 to 4.4 level Celsius) temperature range. A temperature level controller is essential to keep the air conditioning system from running chillier than the preferred fermentation temperature. Temperature level controllers are easily available to purchase from homebrewing suppliers in the $50 to $100 rate range. If utilizing a refrigerator or freezer for fermentation temperature level control, it has to be big enough to hold your fermenting vessel and be offered for the work for the time called for. Utilized fridges and also fridges freezer can typically be acquired relatively cheaply and just run when needed for fermenting or conditioning a batch of beer.

Maintaining it warm

During certain times of the year a garage or cellar brewery might not be warm enough for ale or mead fermentation. It after that comes to be necessary to develop means to maintain a fermentation cozy without investing the energy (and money) keeping the whole house or brewing location at the correct temperature.

Perhaps the easiest technique to warm a fermenter is to cover as well as cover it with a blanket or other shielding material to maintain the warmth produced by the fermentation. A self-adhesive thermostat strip makes keeping track of the temperature level of the fermenting vessel simple.

If conserving the warm generated by the fermentation is inadequate, there are additionally means to include warmth to the system. In the past, I have utilized an economical completely submersible aquarium heating system to warm water held in a big bathtub in which my carboy was positioned. A self sticky thermometer strip on my carboy allowed me to monitor the temperature level as I readjusted the thermostat on the fish tank heater to achieve the desired temperature level.

The other side of using an insulated box (such as the Boy of Fermentation Refrigerator pointed out earlier) to keep fermentation cool is to gear a light bulb inside package to maintain it warm and control the light using a temperature controller. Treatment must be required certain the warm bulb will not get in touch with any surface area that can thaw or catch fire.

For a couple of dollars much more, there are items such as the Fermwrap, an adaptable electric home heating coat that supplies warmth over its entire surface and is therefore safe to make use of on glass carboys or plastic pails. The Fermwrap will commonly elevate the temperature of a five-gallon (19-L) batch an additional 10 levels Fahrenheit (5 levels Celsius). Furthermore, the Fermwrap can additionally be coupled with a temperature controller as well as stopper thermowell to control the temperature level with more accuracy.

Shoot the moon

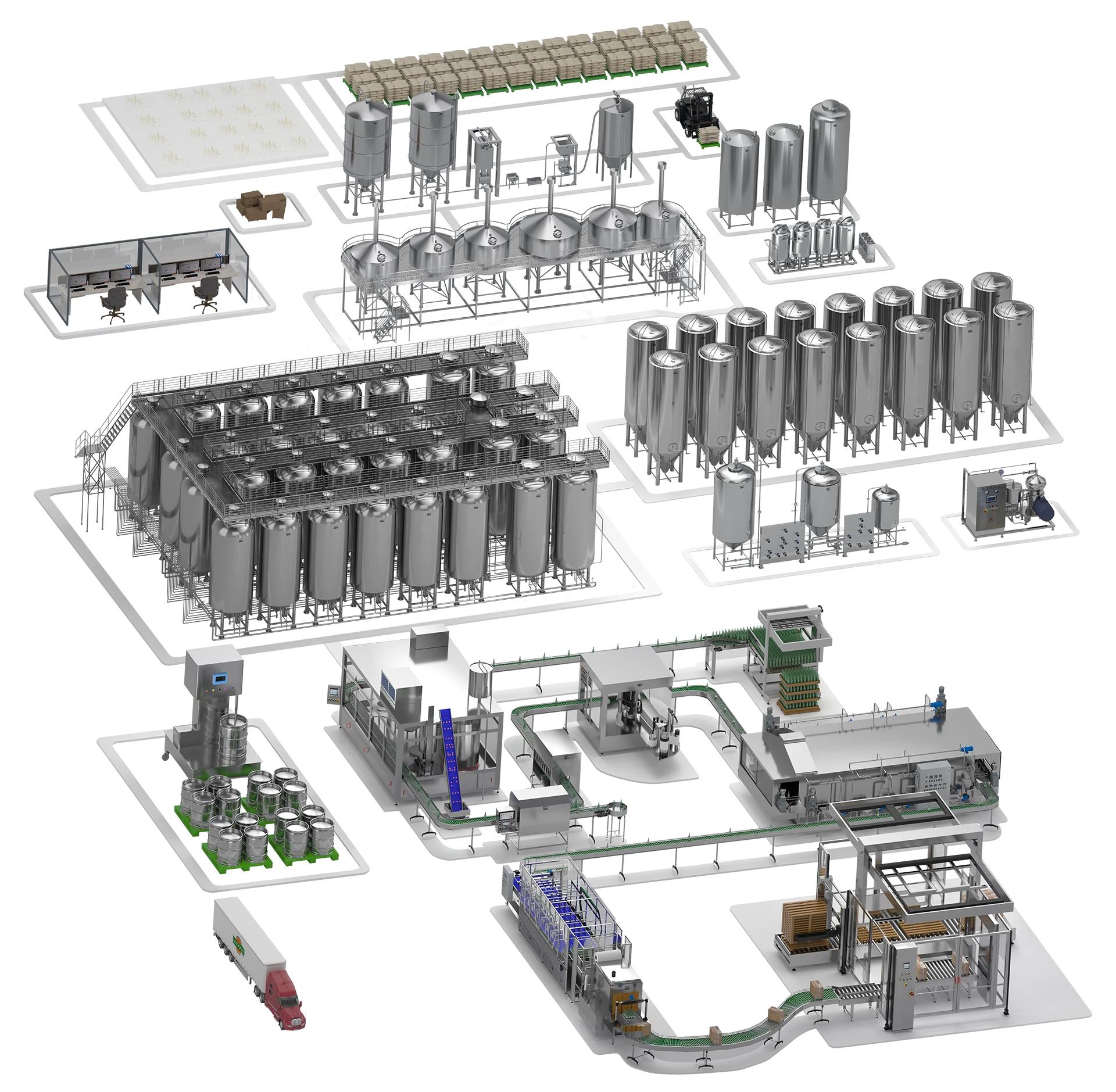

If cash is no things, you can go for the supreme in temperature controlled fermentation with a glycol-jacketed conical fermenter with self-supporting air conditioning and also home heating ability such as the design visualized on web page 65 for $1,500 to $2,500 (I can fantasize, can't I?). These devices are thermostatically regulated to cool down or heat up the wort as required to manage the temperature in a slim array. Some designs are programmable to ferment, do a diacetyl remainder, then brew.

Regular ale fermentation temperatures range from 68 to 72 掳 F (20 to 22 掳 C) as well as ale fermentation temperatures from 45 to 55 掳 F (7 to 13 掳 C). A self sticky temperature level strip put on the exterior of a fermenting vessel above the degree of an ice water bathroom can provide a simple and also practical ways of keeping track of wort temperature during fermentation.

The temperature controller can be used to manage the recirculating pump so it will certainly pump chilly water around the fermenter whenever the temperature of the fermenting wort rises above the desired temperature level. Temperature level controllers come in both analog as well as digital models as well as have between a 1 and also 4 degree Fahrenheit (0.5 to 2.2 degree Celsius) differential respectively, thus keeping the system they manage in a 2 to 8 degree Fahrenheit (1.1 to 4.4 degree Celsius) temperature level range. A temperature controller is necessary to maintain the cooling system from running cooler than the desired fermentation temperature.

Get A Quote