.jpg)

What is pot souring? It is a developing method which enables the maker to sour unfermented wort extremely promptly, between 24 and 72 hrs in most cases.

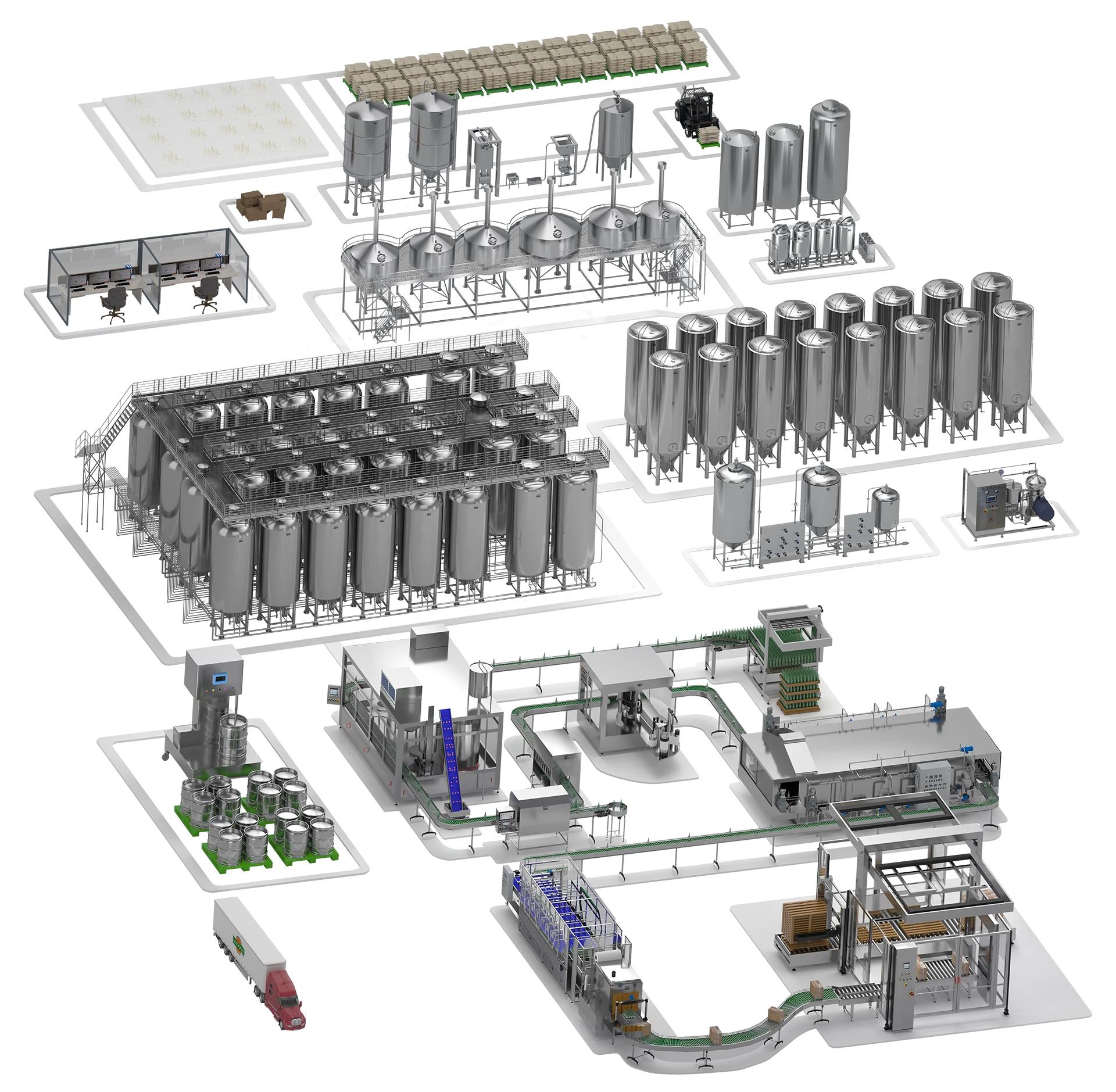

The "pot" is a piece of brewery equipment called the mixture pot, the vessel in which the beer is soured. It is a stainless-steel mash tun where the souring procedure takes place, and afterwards the beer is left to ferment in a container. The crucial distinction in between pot sours and standard sours is that a steel vessel is utilized, in contrast to a barrel.

Why Use Kettle Souring?

Souring a beer using the pot souring technique offers the maker numerous advantages.

Timespan: Being able to turn a beer sour quickly, while maintaining all the various other crucial key preference notes, is a noticeable benefit of kettle souring.

No contamination: The wort is soured and then steamed to kill off the Lactobacillus Acidophilus, and there's no fret about polluting various other batches or contaminating any other tools in your fermentation location.

Flavor control: The Lactobacillus is incredibly conscious isomerized alpha-acids (just 2 IBUs!); this souring approach enables you to make a beer packed full of hoppy taste, much more so than what is possible when utilizing the typical technique.

Exactly How to Prepare Sanitary Wort?

Prior to pitching the Lactobacillus, the wort must be prepared.

The wort is flash-boiled for regarding 10 minutes to exterminate any kind of organisms that have actually made it through as much as this factor. This procedure additionally repels oxygen introduced right into the mix, as well as this aids safeguard versus unwanted bacteria blossoms.

What Should the Wort Temperature Be for Kettle Souring?

115 ° F( 46 ° C )is the conventional temperature level for pot souring with Lactobacillus, yet brewers each have their own magic temperature level, anywhere in between 95 ° F (35 ° C) to 115 ° F( 46 ° C). These temperatures offer the very best mix of flavor and also speed for a fast sour beer.

If the brewer is using a lactic acid bacteria obtained from an industrial supplier (as opposed to getting it from natural resources), it's always best to adhere to the throwing price as well as temperature level suggested by the provider.

After boiling, the wort has to be cooled off to around 95-- 115ºF (35-46ºC) in order to incubate the lactobacillus, depending on the strain. This is conveniently done by running the wort with a tube heat exchanger. Not just does this awesome the wort, however additionally provides sanitization (although hot wort additionally provides a certain level of protection from undesirable microorganisms blooms).

What should the Wort Ph be for Kettle Souring?

Pre-acidification of the wort to pH 4.0-4.5, accomplished by using a food quality basic acid (lactic or phosphoric), does wonders when it comes to inhibiting various other microbial strains that might be present in the wort (such as enteric bacteria). Lactobacillus does not produce protease that breaks down foam proteins below pH 5.0.

This acidification likewise hampers the enzyme action Lactobacillus makes use of when it comes to breaking down healthy proteins. This indicates the resulting beer will certainly showcase all the head retention and also body that you would certainly expect from a beer fermented using just Saccharomyces.

During this time around, CO2 can be added on top of the wort (or gurgled with it) to develop a 'bed'. This protects against any type of more cardio microbial action. Conversely, another jacketed vessel, such as a fermenter or a wort receiver, can be removed with CO2 and also the wort transferred right into this vessel to free up your pot for even more developing.

Pitching Lactobacillus Guide

For fresh grain, about 2L (about 2.5 pounds or 1.15 kg) of grain per 10/bbl in a mesh bag held at 115ºF (46ºC) will go down pH from 5.2 to 3.2 in around 14 hrs.

For other techniques, between 100ºF-118ºF (38ºC-48ºC) might work. Start with a starter batch if you doubt.

Once again, if you are using lactic acid germs from a business supplier, comply with the throwing price as well as temperature they advise.

What should the Wort Ph want Kettle Souring?

The target final pH must be between 3.0 and also 3.5, relying on the wanted sour taste of your dish.

Kettle Souring Tips and Hints

Do not fail to remember to boil wort again after kettle souring.

Do not use any hops till the last boil. Jumps seriously prevent Lactobacillus.

Pitch plenty of yeast when you're ready for fermentation. The yeast cells will need to fight a little bit versus the level of acidity.

That's all the suggestions we have to provide on this very fascinating (and also scrumptious!) process. Please contact us if you would like any more guidance on equipment.

It is a stainless-steel mash tun where the souring procedure takes area, and after that the beer is left to ferment in a container. The key difference in between pot sours and also typical sours is that a steel vessel is made use of, as opposed to a barrel.

After steaming, the wort has actually to be cooled down to around 95-- 115ºF (35-46ºC) in order to nurture the lactobacillus, depending on the stress. This is quickly done by running the wort with a tube heat exchanger. Not only does this awesome the wort, yet additionally offers sanitization (although warm wort additionally offers a particular level of defense from unwanted microorganisms flowers).

Get A Quote