Whirlpool tun in the brewhouse system

.jpg)

Created at the Moosehead Brewery in New Brunswick, Canada in 1960, the whirlpool vessel is now an usual approach of dividing hop fragments as well as other solid particles from warm wort. This vessel is additionally sometimes referred to as "hot wort settling tank." The concept of the whirlpool tank is that centripetal pressures will certainly cause strong particles suspended in a revolving mass of fluid to migrate to the center of the bottom of the vessel in a cone-shaped mass. Trub, a sediment having jump pieces as well as solid protein-based particles, must be eliminated prior to the wort can be chilled as well as sent to a fermenting vessel. In order to work correctly, a whirlpool tank have to be a vertical cylinder with a flat bottom as well as the storage tank size have to go to least equal to the depth of the wort when the tank is full. Deep storage tanks with a tiny diameter will certainly not work well. The whirlpool effect is accomplished by pumping the wort via an inlet line located above an elevation over 1/3 of the storage tank's depth; the inlet pipe must be turned tangentially as well as can also be sized much less than the diameter of the primary wort line so regarding raise the wort turning inside of the tank. It is very important to keep in mind that any kind of blockage inside the tank will develop eddy-currents that will upset the smooth rotation of the wort, delay settling, as well as reduce the compactness of the trub pile. The bottom of the container should have a 1% slope toward the container outlet, which should lie near the tank wall surface and also not in the center of the container. As the warm wort is swirled in the whirpool storage tank, the debris gathers into the facility, creating a "trub cone" as well as leaving the remainder of the wort clear. Once the wort pertains to a remainder, it will be pumped to the chilling apparatus from a port near the wall of the vessel, leaving the trub cone in the center. As soon as the wort is exiled to the fermentation vessel, the trub cone can be disposed of though a port located in the facility of the vessel.

The innovation of the whirlpool vessel made making use of pelletized hops typical in developing; without it, the tiny pieces of jumps had in the pellets are extremely challenging to get rid of from the wort. While the whirlpool is normally a different vessel in larger breweries, lots of smaller breweries will make use of a mixed kettle/whirlpool vessel. This vessel can complete both the boiling function as well as the subsequent whirlpool feature, yet is thought about a concession, as it rarely can do either of these jobs rather as well as different vessels specifically designed to do each.

In order to work appropriately, a whirlpool storage tank must be an upright cyndrical tube with a level base and also the tank diameter must be at the very least equivalent to the deepness of the wort when the tank is complete. The whirlpool result is attained by pumping the wort via an inlet line located above an elevation over 1/3 of the storage tank's deepness; the inlet pipe must be transformed tangentially and also can also be sized less than the diameter of the major wort line so as to enhance the wort turning inside of the container. The base of the tank must have a 1% slope towards the container electrical outlet, which need to be located near the storage tank wall and not in the center of the tank.

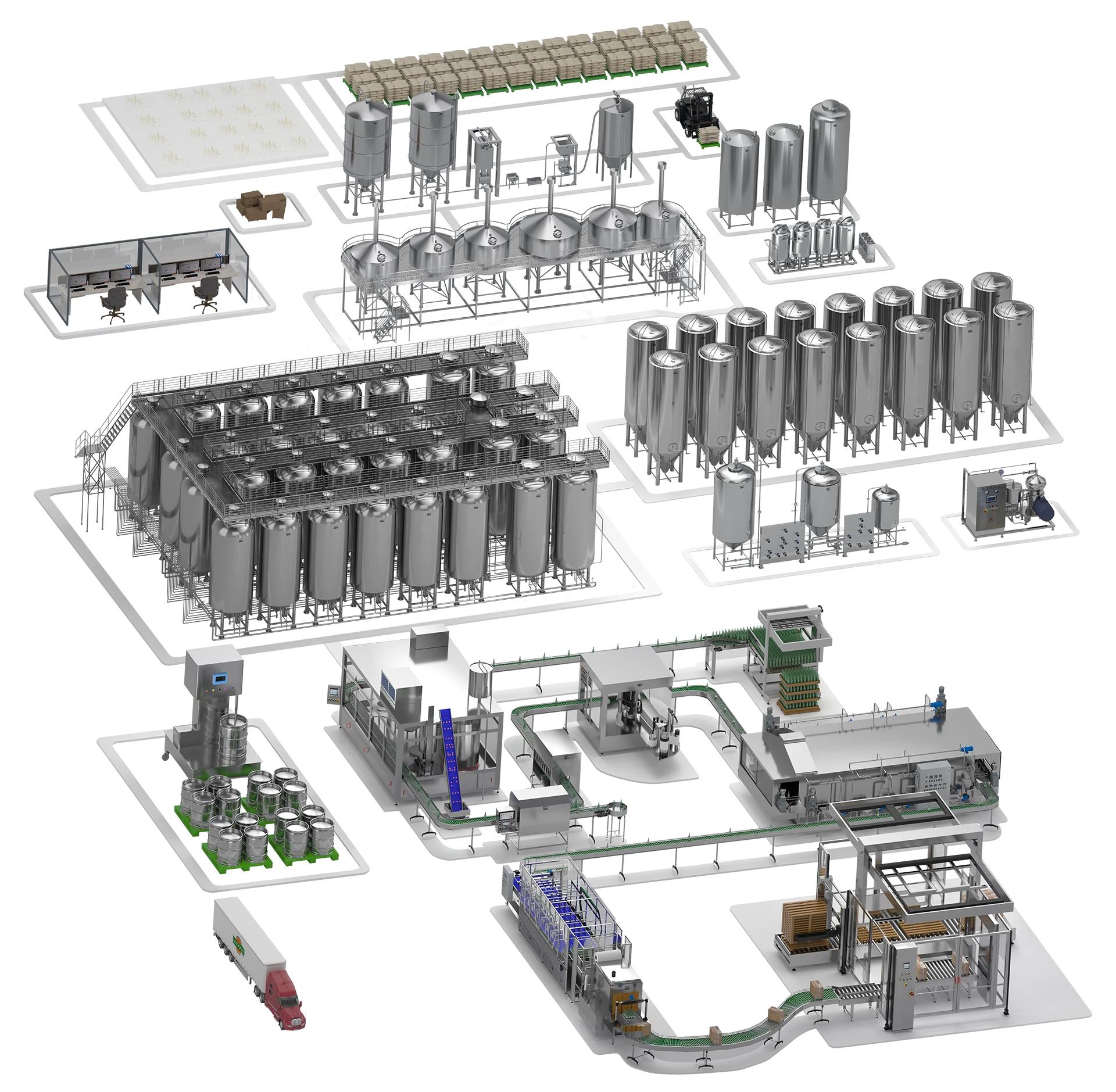

Get A Quote