Dry hopping tank or hop gun with beer fermenters, which is better in brewery?

Both dry hopping tanks and hop guns are commonly used in the beer brewing industry for dry hopping beer. Each method has its own advantages and disadvantages, and the choice ultimately depends on the specific needs and pr...

Read MoreWhy is the beer fermentation tank a conical design?

Fermentation is a crucial link in the beer production process, and the design of the fermenter has a direct impact on beer fermentation. Now most breweries will be equipped with different numbers of conical fermentation t...

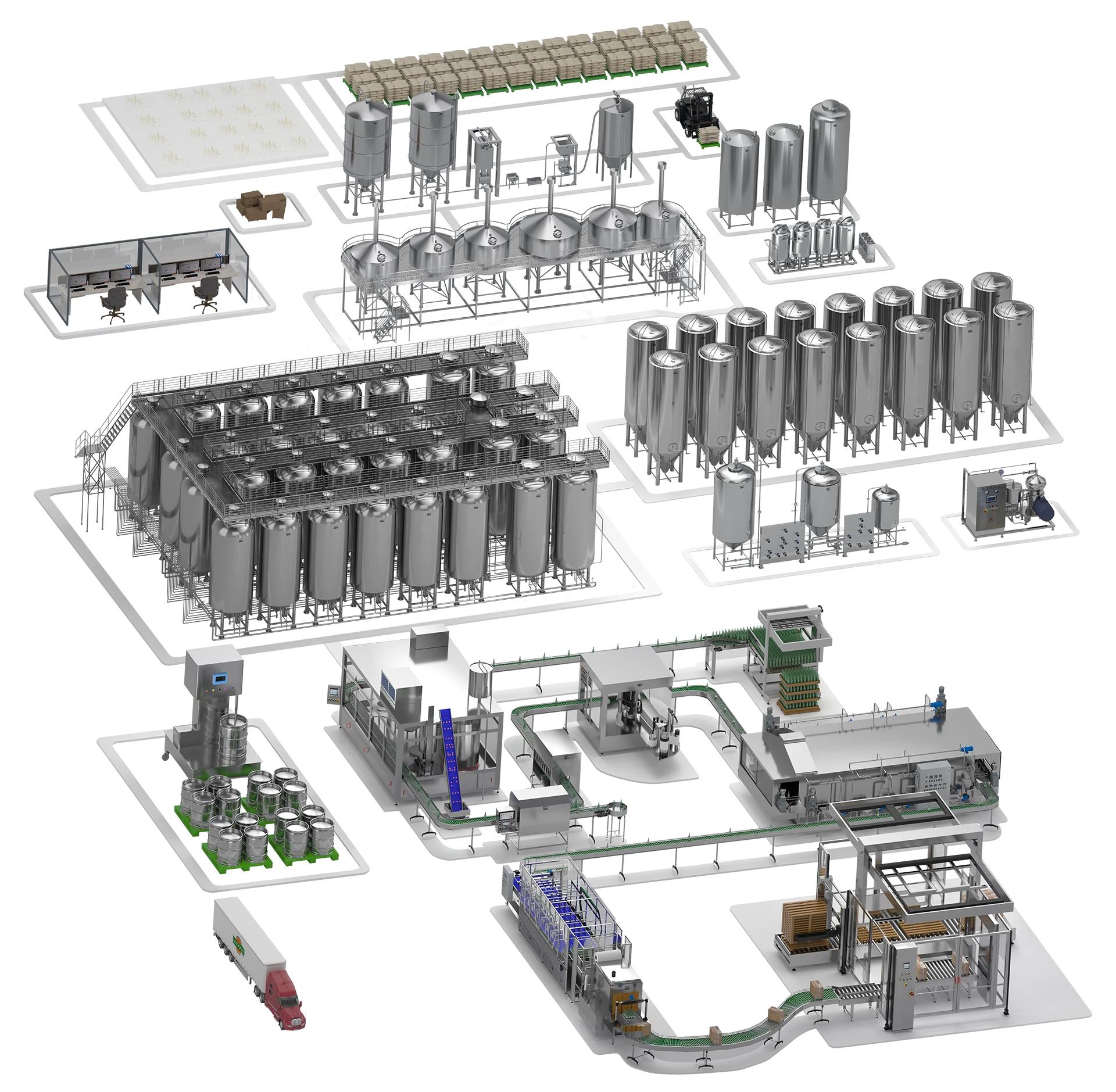

Read MoreWhat Included in a Whole Brewery System from Tiantai

Hi, here is Sharon from Tiantai Beer Equipment Co., Ltd. Welcome to visit our brewery equipment website! Here Id like to introduce some detailed information of our brewery equipment to you, let see what mainly included in...

Read MoreHot Selling Micro Brewery Equipment from TIANTAI

Hi, here is Sharon from Tiantai Beer Equipment Co., Ltd. Welcome to visit our brewery equipment website! The micro sizes of brewery equipment (2HL-10HL) are always the most common and popular selections among all the firs...

Read MoreThe Reason Why Most Brewery Equipment Is Stainless Steel

When it comes to brewing beer, one of the most important aspects is the right equipment. For this reason, breweries invest in high-quality stainless steel equipment, which not only helps to scale up production, but also a...

Read More3 Ways Of a Beer Brewing System Working With Different Equipment

When it comes to brewing beer, there are three main ways that are used to create a variety of different styles and flavours. They are known as extract brewing, partial wort brewing and all-grain brewing. Extract brewing i...

Read MoreWhat is the approximate cost of setting up a 500L brewery system?

If youre looking to start a brewery, one of the first questions youre likely to have is: how much will it cost to set up a 500L brewery system? The answer, of course, will depend on a variety of factors, including the qua...

Read MoreHow to choose the material of glycol pipeline for your brewing system?

When it comes to building a brewing system, one crucial element that can often be overlooked is the glycol pipeline. The glycol pipeline is responsible for keeping your brewing systems temperature at a consistent level, e...

Read More.jpg)