How to choose a good beer brewing equipment manufacturer?

When choosing a good beer brewing equipment manufacturer for your brewery, it is important to consider the following factors....

Read MoreSome Points To Keep In Mind When Using Craft Beer Fermentation Tanks

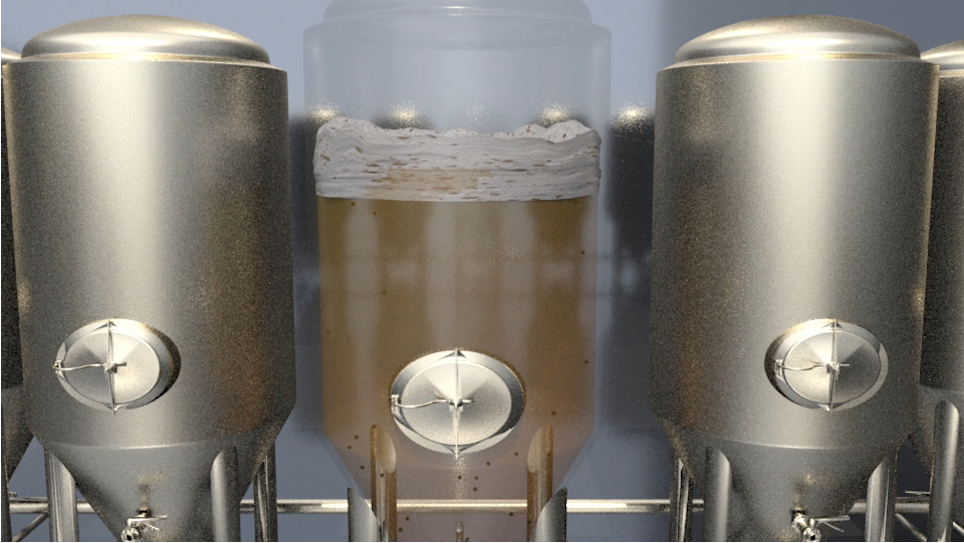

Today wewill discuss with you the essentials whenusing craft beer fermentation tanks. The type of yeast we choose to use, the strength of the fermenting wort, whether we are brewing commercially or at home, and the final ...

Read MoreCommon Equipment Configuration In a Craft Beer Brewing System

The main body of the craft beer equipment includes the brewhousesystem, fermentation system, filtration system, CIP cleaning system, power distribution system, thermostatic control system, refrigeration system, distributi...

Read MoreWhat chemicals are usually used to clean beer brewing equipment in brewery equipment CIP?

As a brewer, you need to understand that a hygienic brewing environment is important to ensure the quality of your beer, and thats where a good clean-in-place (CIP) system comes in. A good CIP system requires the associat...

Read MoreWhat factors will affect the fermentation of beer when brewing beer using a beer brewing system?

The type of yeast we choose to use, the concentration of wort to ferment and the final alcohol concentration we expect to achieve all affect the beer fermentation process. S ugar C ontent Sugar is the source of alcohol. N...

Read MoreLearn About The Craft Beer Output Of Your Brewery Equipment

The output of beer brewing depends on the type and size of brewing equipment, the amount of beer brewed, the size and number of fermenters and the fermentation cycle of the beer. Putting these factors together, which fact...

Read MoreThe Importance Of Polishing Stainless Steel Brewery Equipment

Brewery equipment is made of steel, a material that can be polished to a high gloss. This polishing process is known as mechanical polishing and gives brewery equipment an attractive appearance and makes it more durable. ...

Read MoreCraft Brewery Equipment Maintenance Program: Steam Boiler

Brewing equipment requires regular maintenance to produce better beer. Steam boilers are a key tool in the brewing of beer. A brewerys boilers must be properly maintained and monitored to maintain optimum performance. As ...

Read More.jpg)

.jpg)

.jpg)