In fact, all the brewhouses are originally four vessel, five vessels even six vessels in big commercial breweries.

Each vessel is in charge of one function, or somewhere each two vessels are in charge of only one function.

For example, some brewmasters prefer to have two kettle tun in their brewhouse system. Like this, the two kettle tun can be working at the same time.(When one is being taken up, the second one can be used at that time.) So they can achieve to brew several batches per day to raise their beer production.

And with the development of craft beer, different combined structures of brewhouses become more and more popular among craft beer brewing field.

For 200lts, 250lts, 300lts, 400lts, 500lts, 600lts, even to 1000lts brewery system, the combined structure is very suitable.

I attached two photos to help you understand its structure.

The structure is Mash/Lauter/Whrilpool tun + Kettle tun.

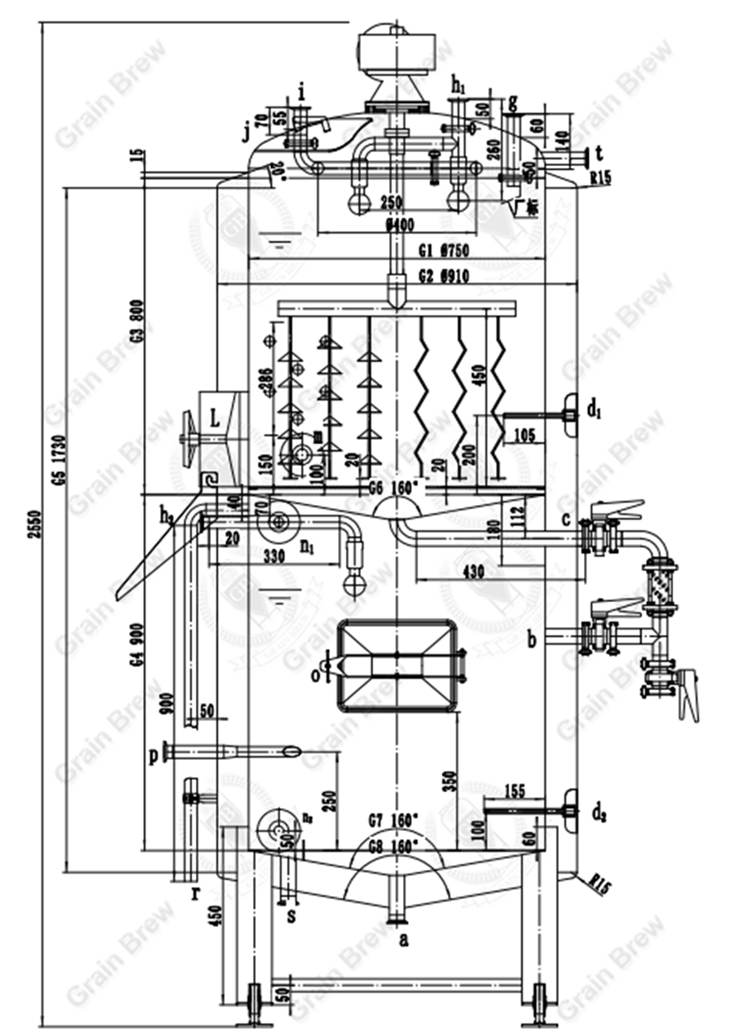

At the moment, I attached drawing of 300lts Mash/Lauter/ Whirlpool tun as below. More details please kindly check there.

In fact, the left taller tank is a combination of two vessels, the upper vessel is mash/lauter tun, and the lower vessel is whirlpool tun.

When we start to filter wort(lautering), the wort can naturely flow into the lower tank(whirlpool tun) by gravity to be collected.

As you know, the gravity filtration is very good filtration method, that is not only fast but also can effectively avoid grist bed stucking. And the most important is that it can help us get very clear filtered wort.

When both wort lautering and sparging are completed, we will pump the filtered wort into kettle tun to heat up and boil for at least 60 mins.

Then after boiling, the hopped wort will be pumped back to whirlpool tun for whirlpooling to separate some protein precipitates and large impurities.

Edited by Damon

Email:[email protected]

.jpg)

Get A Quote