We know that fermentation requires a large amount of yeast, and yeast reproduction requires oxygen. For this, we must provide enough oxygen to the yeast in the fermentation stage.

There are many ways to oxygenate wort. Tiantai beer equipment is used more and has better effect as follows:

Venturi Tube Oxygenation Device

The use of venturi tubes for wort aeration is a common method used in breweries. As shown in the figure below, there is a narrow pipe diameter section to increase the flow rate, and the wort forms a vortex in the pipe diameter widened section. The air enters the pipeline through the nozzle, and the turbulent wort fully contacts and mixes with the finely dispersed air bubbles.

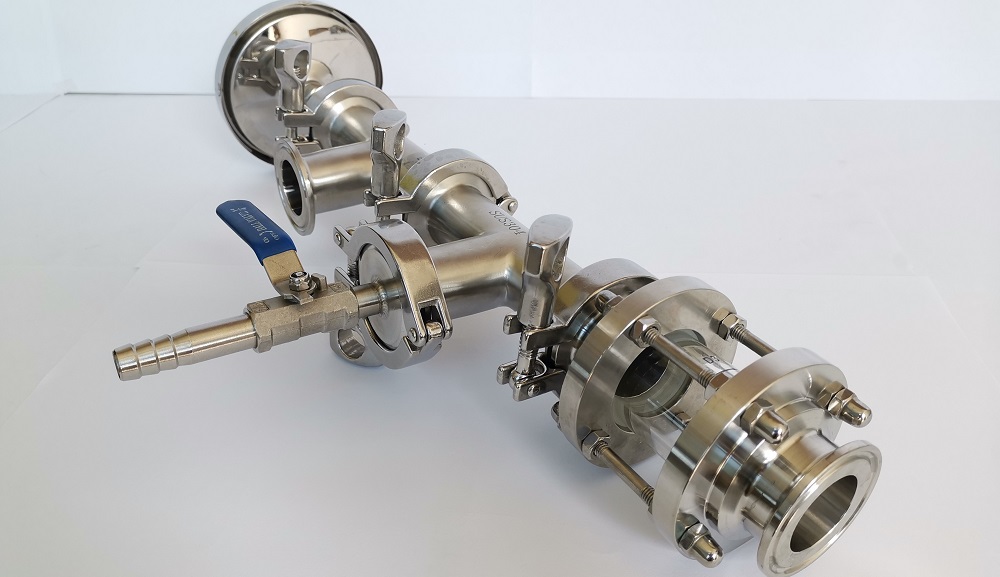

Titanium Rod Oxygenation Device

Titanium Rod Oxygenation Units are a popular choice for wort oxygenation in microbreweries and distilleries. The effect of this oxygenation is optimal. Insert the titanium rod into the titanium rod interface on the oxygenation device, and the direction of the air intake is opposed to the flow direction of the wort. The porous structure of the titanium rod helps to disperse the injected air or oxygen into fine bubbles, and the oxygen can be better integrated into the wort.

Venturi VS Titanium Rod Oxygenation

Although the porous junction of the titanium rod helps to improve the solubility of oxygen, it is also difficult to clean and easy to block, so the service life of the titanium rod is short, and it needs to be replaced in time after a certain batch of brewing. Venturi tube oxygenation is generally used in conjunction with an air compressor, a three-stage filter and a sterile filter to inject the filtered and purified sterile air into the wort. CIP can be used to clean or disassemble to clean the inner wall of the Venturi tube, and the service life is long.

When the same gas is selected, the effect of the titanium rod oxygenation device will be higher than that of the Venturi tube oxygenation device, and the waste of gas is small. However, considering the maintenance cost, the Venturi tube oxygenation device has a long service life and low maintenance cost.

In terms of gas selection for oxygenation, pure oxygen is often used for small-volume brewing; sterile air is used for large-volume breweries. This is because the use of air oxygenation often requires more wort mixing, and the oxygenation time is long. If the wort production is insufficient, the expected oxygenation amount cannot be achieved.

Therefore, for wort oxygenation, small equipment uses titanium rods and pure oxygen cylinders; brewery equipment uses Venturi tubes, air compressors, three-stage air filters and sterile air filters. However, for breweries with limited initial investment, it is also possible to use a Venturi tube and pure oxygen cylinders for oxygenation first, and then add air compressors and other equipment later.

Tiantai will recommend the most suitable brewing solution for you according to your specific needs and actual situation. If you have any questions, warmly welcome your inquiry.

Edited by Cassie

E-mail:[email protected]

Get A Quote