Currently, single malt whisky holds a prominent position in the global spirits market. Renowned for its distinct character and exceptional quality, single malt whisky has gained popularity among connoisseurs worldwide. Crafted from 100% malted barley in a single distillery, this type of whisky embodies the unique flavors and aromas of its specific origin. With an emphasis on traditional production methods and aging in oak casks, single malt whisky continues to captivate enthusiasts, making it a sought-after spirit across the globe.

Today I am very happy to discuss with you the equipment needed to brew single malt whiskey.

Malt Miller

Our Malt Miller features two rollers with different speeds to enhance malt efficiency. This equipment expertly mills or crushes the malt, breaking apart the kernels and exposing the cotyledon, which is crucial for extracting the desired flavors during mashing.

Mash Tun, Lauter Tun, or Mash/Lauter Tun

These vessels play a vital role in the mashing process, facilitating the conversion of starches in the malted barley into fermentable sugars.

Here it can be equipped with Mash Tun and Lauter Tun or Mash/Lauter Tun according to the needs.:)

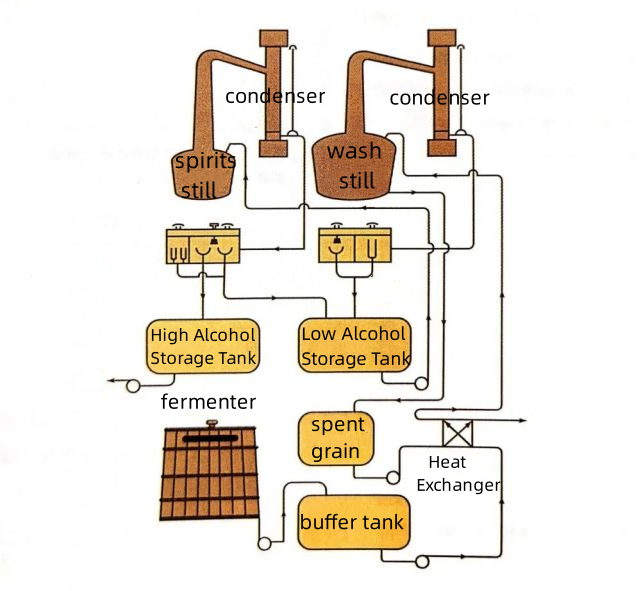

Buffer Tank

The Buffer Tank serves as a storage unit for the third washing water, which can be used for subsequent mashing, as well as for storing the lautered wort. We offer both smaller and larger tanks based on your requirements.

Heat Exchanger

Our Heat Exchanger efficiently cools the wort, promoting rapid yeast pitching and fermentation. This vital equipment ensures proper temperature control, allowing for consistent fermentation and optimal flavor development.

Fermenter

Our Fermenters are designed to provide an ideal environment for fermenting the wort. These vessels maintain temperature and pressure conditions, allowing yeast to convert sugars into alcohol, resulting in the desired whisky characteristics.

Wash Still

The Wash Still is utilized for the first distillation process, separating alcohol from the wash. It plays a crucial role in establishing the foundation of the whisky's flavor profile.

Spirits Still

The Spirits Still is employed during the second distillation, refining the alcohol obtained from the wash still. This step further enhances the purity, aroma, and complexity of the whisky.

Low Alcohol Storage Tank

The Low Alcohol Storage Tank is specifically designed to store the low-alcohol liquor obtained from the first distillation process. It ensures proper maturation and aging before proceeding to the next stage.

High Alcohol Storage Tank

The High Alcohol Storage Tank is dedicated to storing the high-alcohol liquor obtained from the second distillation. This vessel allows for proper maturation and aging, ensuring the whisky reaches its full potential.

Glycol Cooling Unit

Our Glycol Cooling Unit provides chilled water for various stages of whisky production, including fermenter cooling, wort cooling, and distillation. It guarantees precise temperature control, contributing to the overall quality and consistency of the final product.

Tiantai specialize not only in providing top-quality beer equipment but also in meeting the unique requirements of whisky production. If you're considering establishing a whisky distillery, do not hesitate to contact Tiantai. We shall be honored to help turn your dream of owning a whisky distillery into a reality in any way we can.

Edited by Cassie

E-mail:[email protected]

Get A Quote