Here is Sharon from Tiantai Beer Equipment Co., Ltd.

Welcome to visit our brewery equipment website!

Here we’d like to introduce the meaning of Hydrators in brewery system to you, any questions or other demands please feel free to contact us for more interested details, Cheers!

In a brewery system, the hydrator is a device used to mix dry grains or powders with water to create a mixture called the mash. The mash is the starting point of the brewing process, which eventually leads to the production of beer.

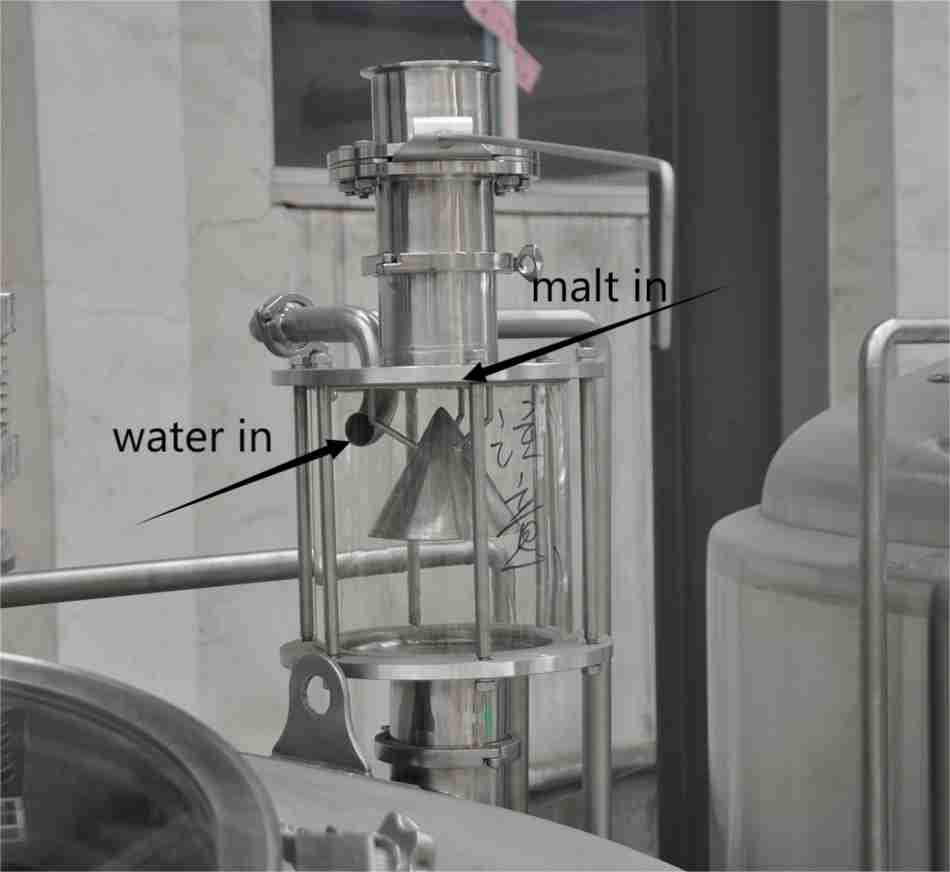

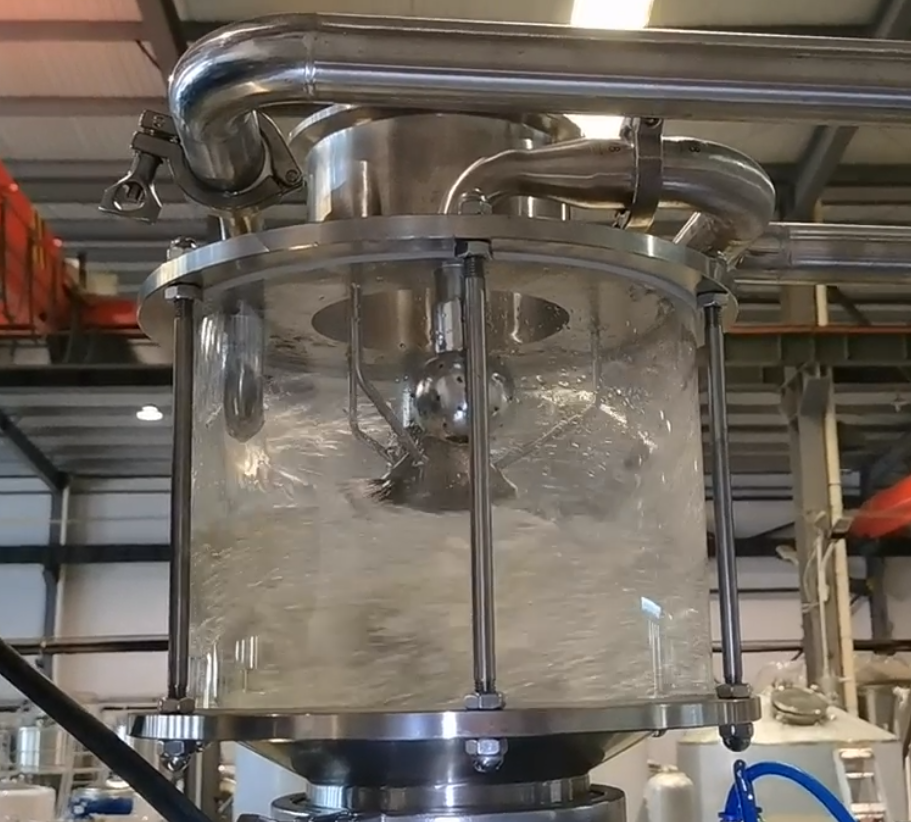

The hydrator typically consists of a vessel or tank with an inlet for water and an outlet for the mash. Dry grains or powders are added to the hydrator through a hopper or a similar mechanism. As water enters the vessel, it mixes with the grains or powders to form a slurry. The hydrator usually contains a stirring device or agitator to ensure thorough mixing of the water and grains/powders.

The temperature of the water used in the hydrator is critical to the brewing process, as it affects the activity of enzymes that break down the complex carbohydrates in the grains into simple sugars. The optimal temperature for mashing is typically between 62-68°C (143-154°F), and the temperature must be carefully controlled during the process.

Once the mash is created, it is transferred to the next stage of the brewing process, where enzymes in the malted grains convert the starches in the mash into fermentable sugars. The resulting liquid, called wort, is then boiled with hops to add flavor and bitterness, and then fermented with yeast to produce beer.

If you have any plans of upgrading your brewery or looking for more tanks to expand your business, feel free to contact us for more details please!

Sharon

Email: [email protected]

Get A Quote