After the mashing process, the decomposition of the macromolecular substances in the malt has been completed. Next, it enters the stage of wort filtering and washing.

Filtration refers to the operation of making the liquid in the suspension pass through the pores of the porous medium under the action of external force, while the solid particles in the suspension are trapped on the medium, thereby realizing the operation of solid and liquid separation.

The primary purpose of filtration is to quickly separate the dissolved soluble and insoluble substances (wheat grains) in the mash in the shortest time to obtain clear wort. At the same time, it is also hoped to obtain a higher leaching rate, reduce oxidation as much as possible, and avoid affecting the color and aroma of the semi-finished wort.

In order to achieve the above purpose, we should try our best to avoid the two major problems of difficult wort filtration and too slow filtration speed.

1. Difficult wort filtration

In the process of wort filtration, the problem of difficulty in filtration often occurs. The occurrence of these problems can be checked and solved from the following four aspects:

(1) Whether the saccharification is complete.

If the saccharification is incomplete and the viscosity of the wort is high, it will affect the filtration. The iodine value of the filtered wort can be checked by iodine liquid on the spot or in the laboratory.

(2) Whether the filtered wort is cloudy.

It may be that the protein decomposition of the mashed mash is insufficient, and the decomposition of β-glucan is not good. Consideration should be given to improving the saccharification process.

(3) Whether there is an error in the filtering operation.

If the filtration speed is too fast at the beginning, tighten the bad layer and re-form the bad layer for filtration.

(4) Whether the temperature of the mash is lowered too much.

A small amount of hot water can be added.

2. Slow filtration speed

The treatment measures for the slow wort filtration in the filter tank should be solved from three aspects: operation, technology and equipment.

(1) In terms of operation:

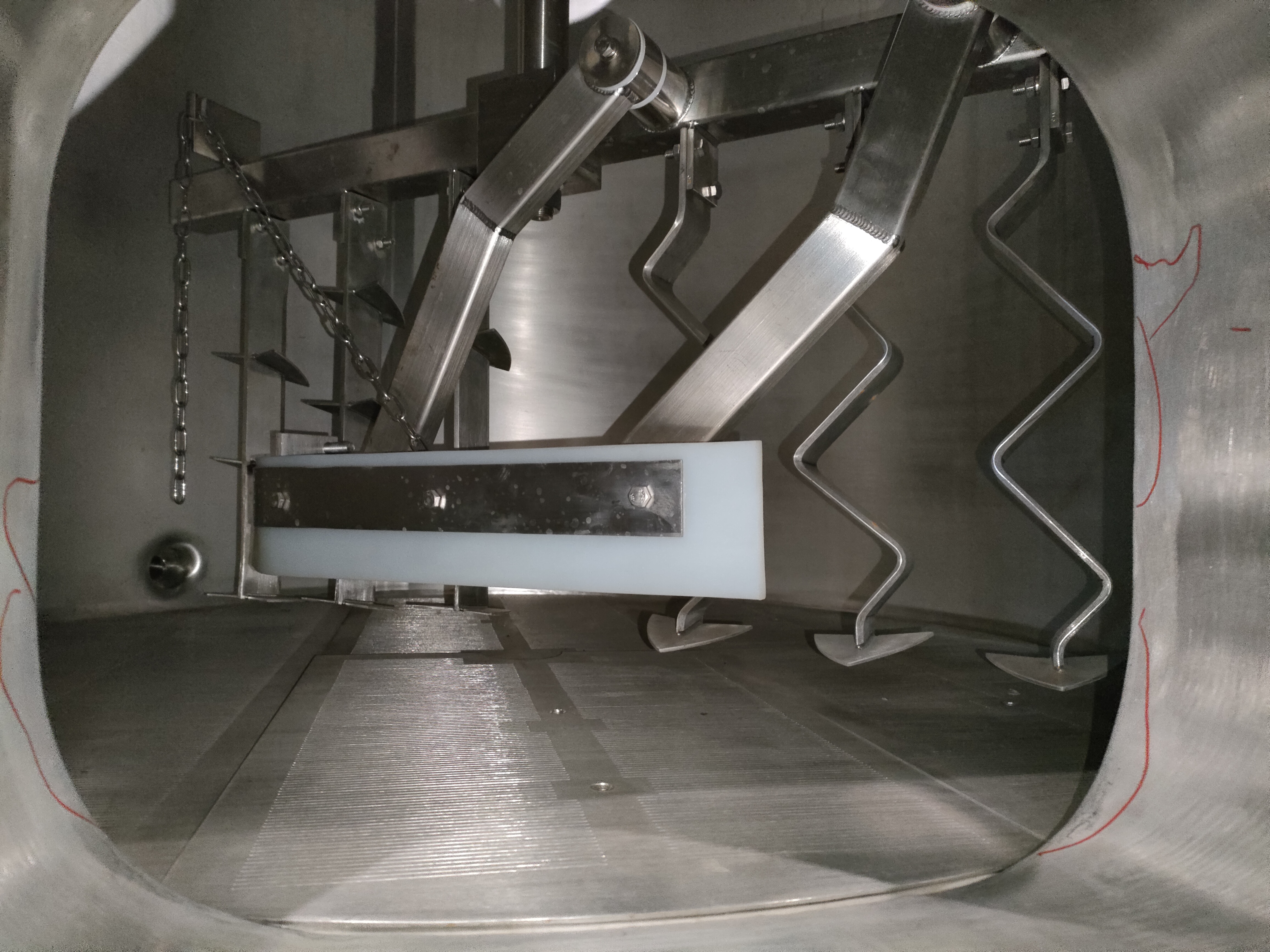

a. Carry out the top water operation on the wort layer, close the wort discharge valve, eject the wort layer from the bottom of the filter tank with 75-80 ℃ hot water, start the cultivator and stir for 5-10 minutes, and re-flow the wort, filter.

b. The wort is re-formed into a filter layer, and the wort knife is lowered to the lowest position for cultivating the wort. After the wort layer is uniform, it is allowed to stand and reflux, and the wort is filtered after clarification.

c. In the process of filtration and grain washing, plough the grains intermittently, and adjust the height of the tiller according to the grain washing speed to reduce the adhesion of the grains surface.

(2) In terms of technology:

a. Adjust the ratio of raw materials and the degree of malt crushing.

b. Use low temperature dipping and protein rest, and prolong the time appropriately.

c. Add an appropriate amount of β-glucanase to reduce the viscosity of the mash.

(3) In terms of equipment:

a. Strengthen cleaning so that the sieve plate is not blocked.

b. Use a good cultivator to strengthen the heat preservation of the filter tank.

Hope the above method can help you.

If you plan to brew or start your own brewery. TIANTAI Brewery equipment could help you answer your questions and supply brewery equipment. We supply 2-150HL complete beer brewing equipment including malt milling equipment, brew houses equipment, beer fermenters /fermentation tank, brite beer tanks, beer bottling machine,beer canning machine, beer kegging machine, hopping machine, yeast propagation equipment. We also supply all auxiliary brewery systems like steam heating pipe and valves, water treatment, filter, air compressor etc. Everything in brewery are all in our list.

Edited by Cassie

E-mail:[email protected]

Get A Quote