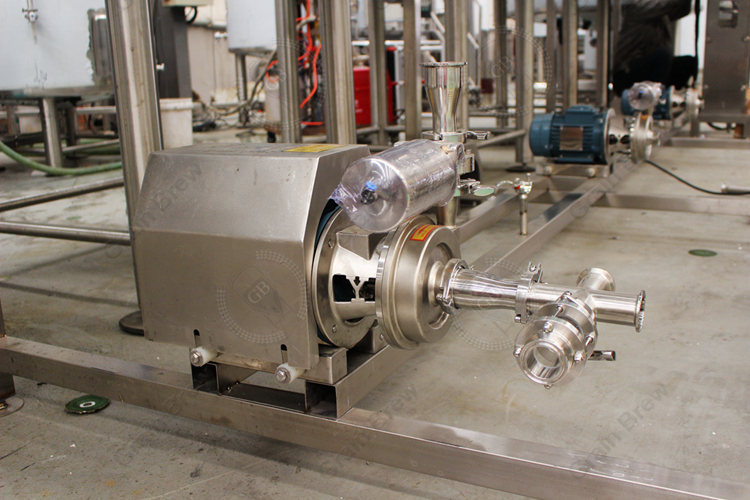

Running Dry of Centrifugal Pumps

In Brewery, centrifual pumps are widely used. In the process of brewing, I believe most of you meet with the pump problem. There will always be a variety of reasons that may cause a centrifugal pump goes run. One of the main reasons for the failure of a centrifugal pump could be running dry.

Some possible phenomenas will occurr during or after the running dry process:

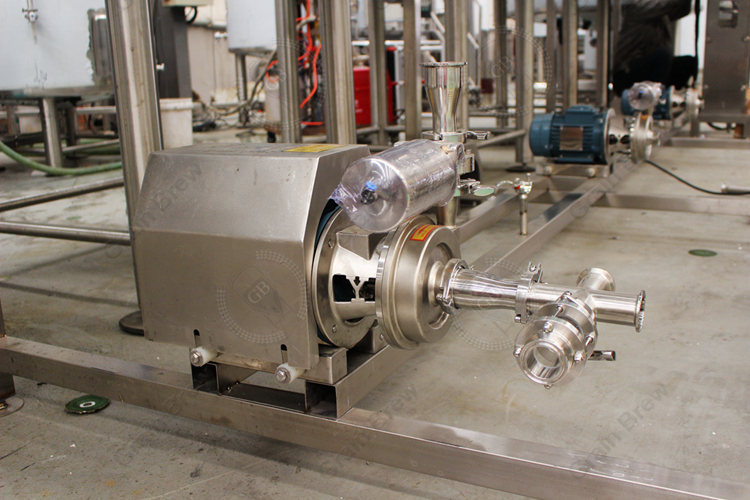

1.The rotating ring and the stationary ring of mechanical seal will continue to have intermittent collisions when pump vibrates. It may cause a leakage and even destroy the seal structure of the pump.

2.The pressing force of rotating ring and stationary ring is consist of medium pressure and Spring's pretightening up force. If pump is running dry, there will be no medium pressure. As a result, the contact pressure of rotating ring and stationary ring will cut down and cause sealing failure.

3.The end face of self-flushing rotating ring and the stationary ring couldn’t be cooled and lubricated if pump is running dry. Dry friction will happen and cause sealing failure.

Antedant Circumstances

Edit by Jane

Grain/Tiantai Beer Equipment Company

E: [email protected]

In Brewery, centrifual pumps are widely used. In the process of brewing, I believe most of you meet with the pump problem. There will always be a variety of reasons that may cause a centrifugal pump goes run. One of the main reasons for the failure of a centrifugal pump could be running dry.

Some possible phenomenas will occurr during or after the running dry process:

1.The rotating ring and the stationary ring of mechanical seal will continue to have intermittent collisions when pump vibrates. It may cause a leakage and even destroy the seal structure of the pump.

2.The pressing force of rotating ring and stationary ring is consist of medium pressure and Spring's pretightening up force. If pump is running dry, there will be no medium pressure. As a result, the contact pressure of rotating ring and stationary ring will cut down and cause sealing failure.

3.The end face of self-flushing rotating ring and the stationary ring couldn’t be cooled and lubricated if pump is running dry. Dry friction will happen and cause sealing failure.

Antedant Circumstances

- Motor current declines

- Pressure fluctuates greatly

- Flow undulates abnormally

- Noise sound appears

- Pump body vibrates

- Pump cylinder temperature rises

Edit by Jane

Grain/Tiantai Beer Equipment Company

E: [email protected]

Get A Quote