Thermal coagulation is an insoluble condensate formed by the condensation of high molecular nitrogen during wort boiling, mainly composed of protein and polyphenol complexes with a diameter of 30-80m. During the wort boiling process, with the continuous oxidation and polymerization of protein denaturation and polyphenolic substances, thermal coagulation will gradually precipitate out, and at the same time, some hop resin and other organic substances will be adsorbed. After the wort is boiled, the thermal coagulation in the wort should be effectively separated as soon as possible to obtain clarified wort.

Today I am very happy to share with you the internal structure and design principles of the Tiantai whirlpool tun.

Tiantai whirlpool tun is an airtight cylindrical container with inclined plane and flat bottom. For the safety of the operators, all Tiantai whirlpool tanks are equipped with insulation layers to prevent the possibility of being burned by the tank wall. The inner wall is smooth and clean, and the inner edge of the tank is flat without edges and corners. It is polished to 0.2 μm and passivated by pickling, which reduces the influence of tank wall friction on the whirlpooling effect from all angles.

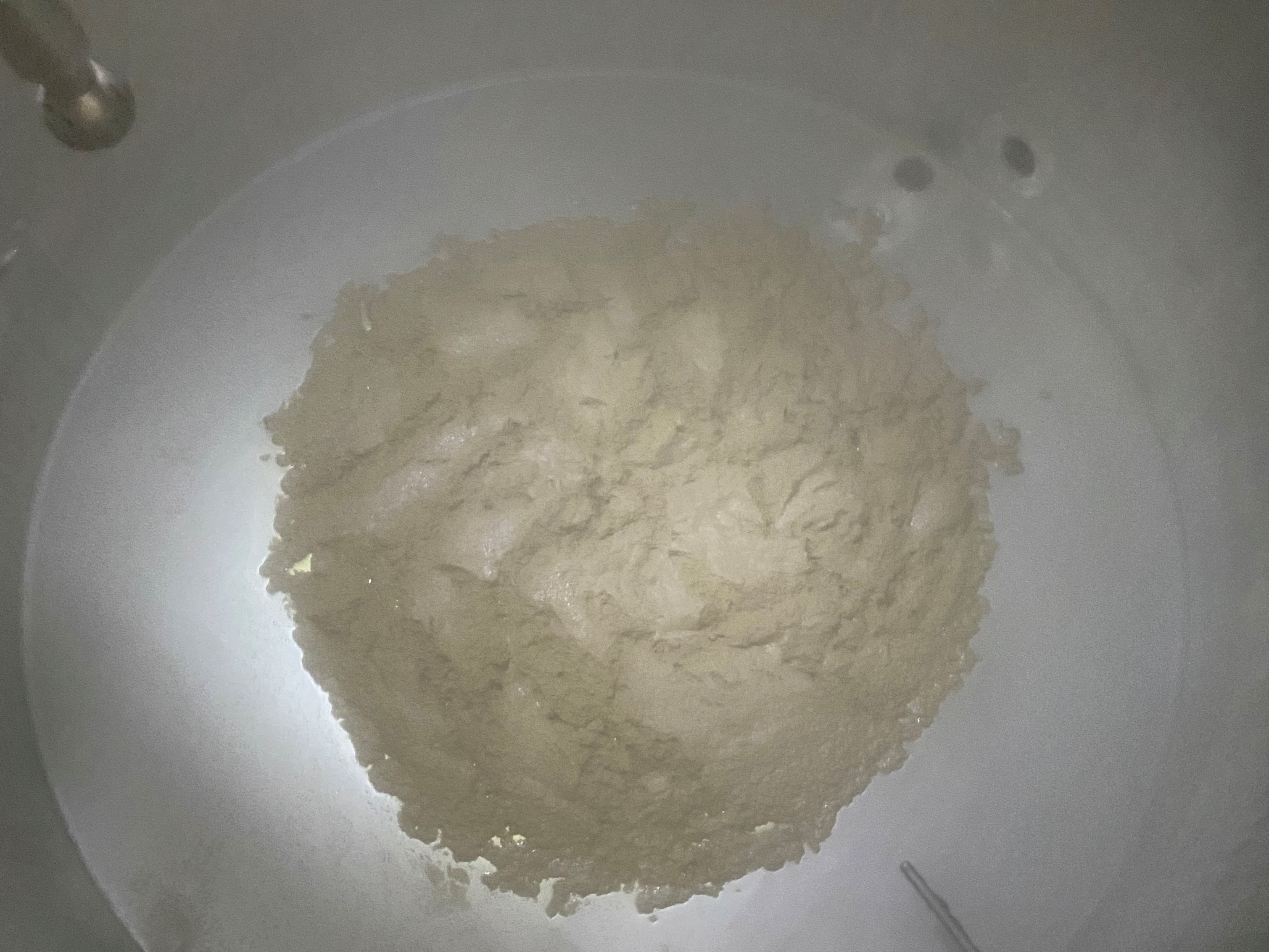

The bottom of Tiantai whirlpool tun is a 2° inclined flat bottom. After boiling, the wort at about 98°C enters the tank along the tangential direction of the tank wall, forming a rotating motion, and the tangent inlet is at a height of 1/3 from the bottom of the tank. After the feeding is finished, the rotating wort is allowed to slow down naturally, resulting in a whirling effect. The force on each point inside the wort varies with the location, and is balanced by centrifugal force and gravity. The upper layer of wort is in contact with the air, and the frictional resistance generated is small, and a concave liquid surface is formed when rotating; the middle layer of wort moves to the surroundings by virtue of centrifugal force; Slow down locally. The solid particles are subjected to relatively large gravity and sink. Under the action of the overall balance, the liquid at the bottom of the tank supplements the upper liquid due to the low-pressure area formed by centrifugal action and generates centripetal force. In this way, under the combined force of gravity and centripetal force, the solids in the wort move closer to the center of the trough. With the natural slowing down of the gyration speed, they settle down and settle in the center of the trough bottom to form mounds, thus achieving solid-liquid purpose of separation.

After standing for 15 minutes, the whirlpooling process is over, and the wort will be rapidly cooled in a plate heat exchanger and then pumped into the fermenter. There are three wort outlets, the two main outlets are at 1/2 of the liquid level and 1/10 of the bottom. The other is used as the residual wort outlet, at the bottom of the whirlpool tun, the opening diameter will be designed according to the height-to-diameter ratio of the tank. The order of opening the valves is from top to bottom, and prevent the wort from flowing too fast, impacting the coagulation precipitated at the bottom of the tank, causing the wort to be turbid.

If you are planning to build a brewery, warm welcome to contact Tiantai to make your brewery dream come true.

Edited by Cassie

Email: [email protected]

Get A Quote